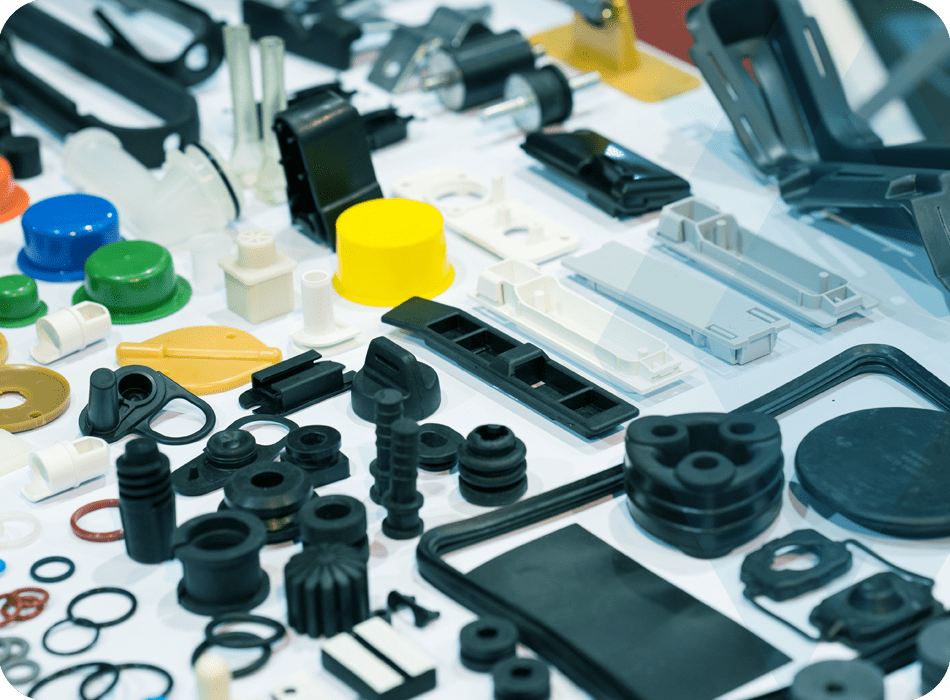

Injection moulding is a key part of modern manufacturing. However, you might be surprised at how often you encounter products that manufacturers create using injection moulding. Indeed, from toys in your home to high-performance equipment in aerospace and sport, this versatile process touches more industries than most people realise.

In this article, we’ll explore 10 unexpected and exciting examples of products made with injection moulding. You’ll discover how plastic innovation powers everyday life—and advanced technologies—behind the scenes.

Why Are So Many Products Made with Injection Moulding Today?

Primarily, manufacturers choose injection moulding because it offers speed, scalability, consistency, and cost-efficiency—especially when producing complex shapes in high volumes. Additionally, it enables designers to work with a range of thermoplastics, deliver high precision, and create strong, lightweight components across numerous sectors.

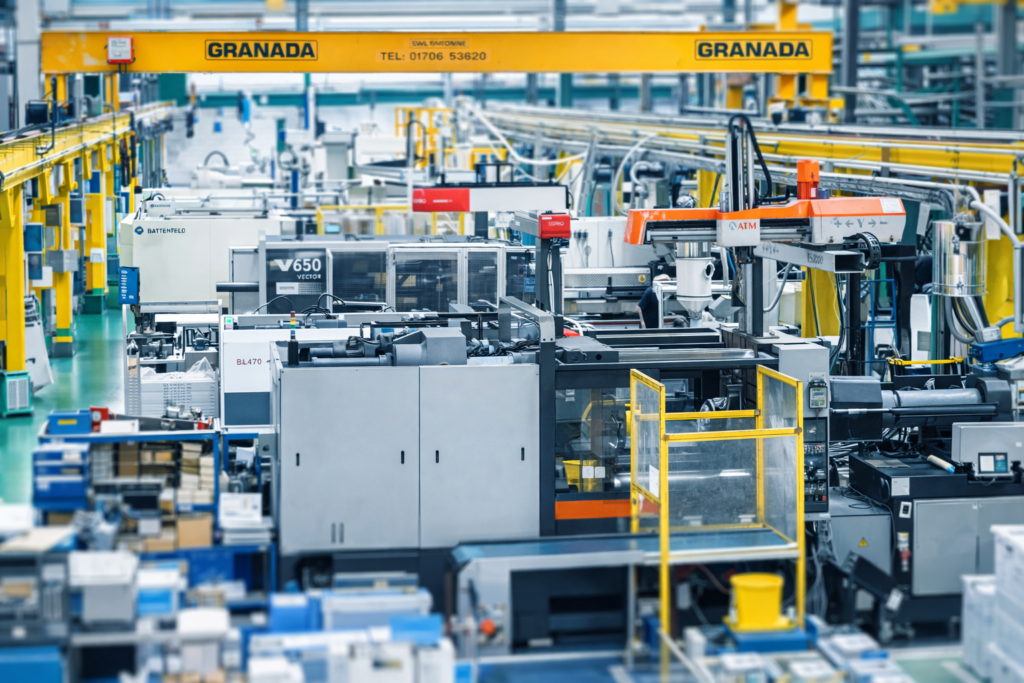

At Flambeau Europe, we specialise in producing complex injection moulded products for industries ranging from medical and automotive to consumer retail and industrial applications. Learn more about our Complete Bespoke Solutions for brands of all sizes.

10 Injection Moulded Products That Might Surprise You

Here are ten examples that show the surprising scope and innovation behind products made with injection moulding.

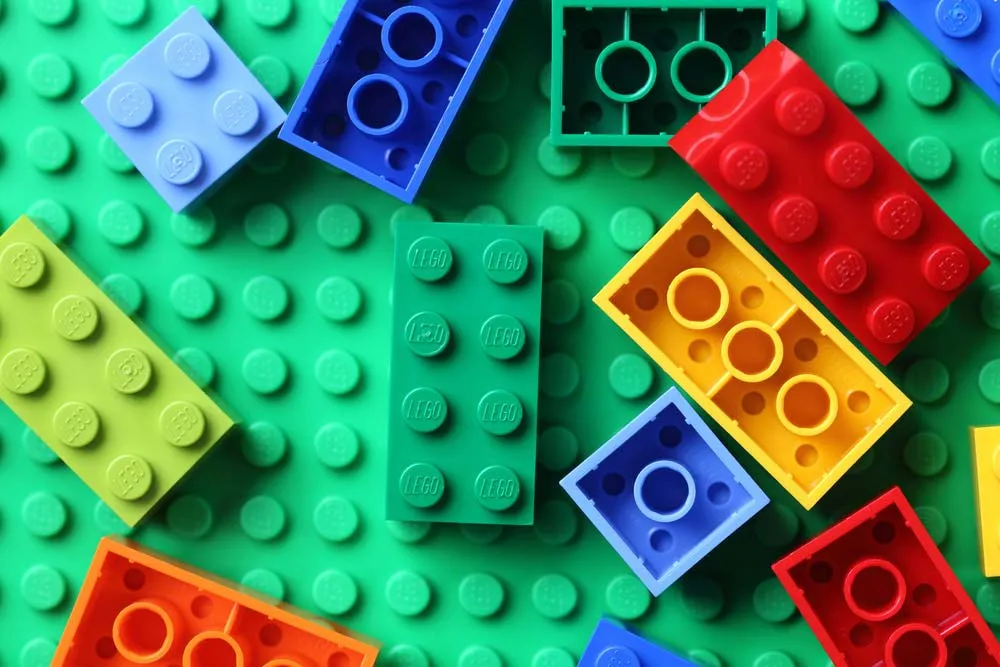

1. LEGO Bricks: Precision in Every Click

Why injection moulding works best:

Specifically, LEGO manufactures its iconic bricks with extreme injection moulding precision, ensuring that every piece clicks perfectly into place—regardless of when or where it was produced.

Why it’s surprising:

Each brick is accurate to within a fraction of a millimetre. With over 36,000 moulds and a global supply chain, injection moulding is the only method that meets LEGO’s demanding quality standards.

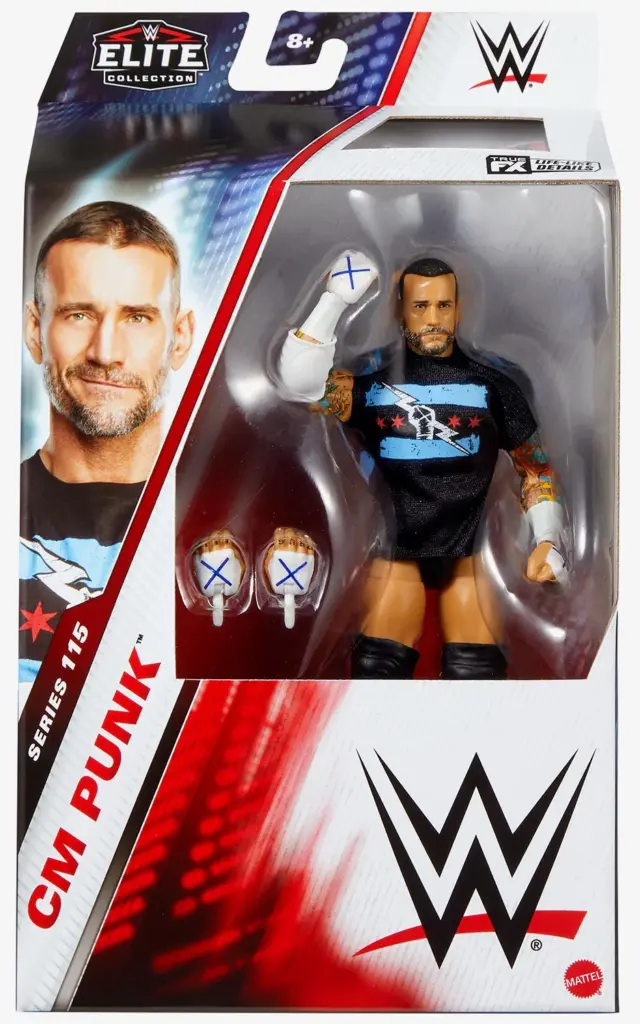

2. Action Figures & Toys: More Complex Than You Think

Why injection moulding works best:

From superhero figurines to plastic animals, toys often feature intricate designs, vibrant colours, and high durability—ideal for injection moulding.

Why it’s surprising:

Many toys that appear simple actually consist of multi-part assemblies made from child-safe polymers, designed for strength, safety, and durability.

3. Aerospace Components: Lightweight and Flight-Ready

Why injection moulding works best:

Injection moulding delivers lightweight, durable parts like clips, housings, and insulation covers—all while meeting strict aerospace standards.

Why it’s surprising:

Aerospace might make you think of carbon fibre and titanium. However, manufacturers mould many non-structural parts to reduce both weight and production costs. For example, according to Airbus, injection moulded thermoplastics help reduce part counts and improve efficiency in aircraft cabins.

4. Sports Gear: Performance You Can Feel

Why injection moulding works best:

Helmets, ski boots, mouthguards, and even bike pedals use moulded thermoplastics for strength, comfort, and protection.

Why it’s surprising:

It’s not just about mass production. Injection moulding supports custom-fitted gear for elite athletes—right up to the Olympic level.

5. Game Controllers: Designed for Grip and Gameplay

Why injection moulding works best:

Modern gaming controllers for Xbox, PlayStation, and Nintendo consoles use moulded shells and mounts to balance strength and ergonomic design.

Why it’s surprising:

You might not realise it, but designers carefully engineer your controller for performance and comfort. Moulded plastic delivers comfort, durability, and a consistent button feel.

(Example of medical-grade product made by Flambeau in the past)

6. Medical-Grade Devices & Containers: Made to Be Trusted

Why injection moulding works best:

Manufacturers use injection moulding to produce syringes, IV lines, pill dispensers, and other devices with high precision and sterility at scale.

Why it’s surprising:

These essential items must meet strict medical regulations. Injection moulding ensures hygienic, repeatable, and cost-effective production.

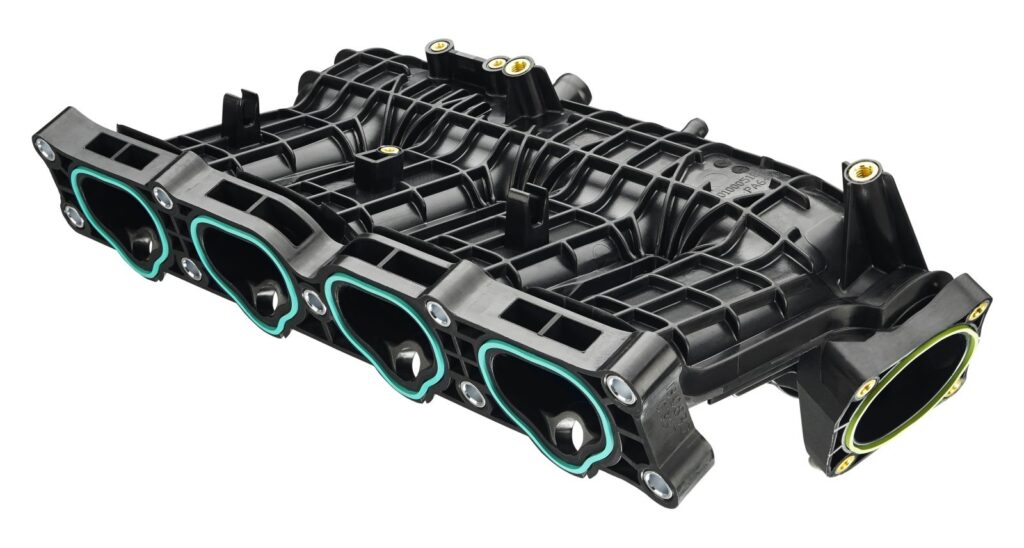

7. Automotive Intake Manifolds: Under-the-Hood Innovation

Why injection moulding works best:

Modern intake manifolds use thermoplastics to reduce vehicle weight and improve performance.

Why it’s surprising:

We expect engines to be mostly metal. Yet, injection moulded parts like manifolds improve fuel economy and reduce emissions—especially in high-performance vehicles.

8. Musical Instruments: Harmonising Plastic and Sound

Why injection moulding works best:

Instrument makers mould plastic parts—such as clarinet mouthpieces or electric guitar pickup housings—to enhance acoustic performance and durability.

Why it’s surprising:

Onstage, these parts go unnoticed. But injection moulding helps ensure consistency in tone and tuning.

9. Formula One Electronics Housings: Racing to Precision

Why injection moulding works best:

Injection moulded housings protect sensitive F1 electronics—like control units, cooling ducts, and sensor modules—from heat and vibration.

Why it’s surprising:

Even at speeds above 200 mph, moulded plastics deliver weight savings and extreme reliability. Engineers deploy these components in some of the world’s most demanding environments.

10. Football Boot Soleplates: Built for Grip and Agility

Why injection moulding works best:

Designers use injection moulding to create stud and soleplate systems that enhance biomechanics, traction, and flexibility on the pitch.

Why it’s surprising:

Although the upper may use knit or leather materials, moulded plastic provides the boot’s grip and performance. ScienceDirect confirms these elements impact speed, control, and injury risk.

What Do These Injection Moulded Products Have in Common?

Although these products come from vastly different industries, they share the same core benefits:

- High production accuracy

- Lightweight, durable construction

- Design flexibility for complex shapes

- Mass production efficiency

- Cost-effectiveness at scale

Ultimately, these advantages explain why you’ll find injection moulded products everywhere—from bedrooms and hospitals to stadiums and space missions.

Why Choosing Injection Moulding for Products Matters for Your Business

Whether you’re designing a medical device, industrial part, or consumer product, injection moulding consistently delivers high-quality, scalable results. At Flambeau Europe, we collaborate with designers and engineers to transform ideas into reality—from rapid prototyping through to full-scale production.

Want to know how we do it? Visit our Complete Bespoke Solutions page or contact our team to start a conversation.

We also take quality seriously—read about our ISO 9001 & 14001 certifications.

Conclusion: Products Made with Injection Moulding Are Everywhere

Indeed, products made with injection moulding are far more diverse—and far more innovative—than many people realise. From LEGO bricks to Formula One, this process powers creativity, performance, and everyday function.

Which one surprised you most? Let us know—or explore how Flambeau Europe can help shape your next product.

Ready to Bring Your Product to Life?

Let’s make it happen. Get in touch with our team to discover how we can support your next injection moulded solution. Or explore our bespoke services.