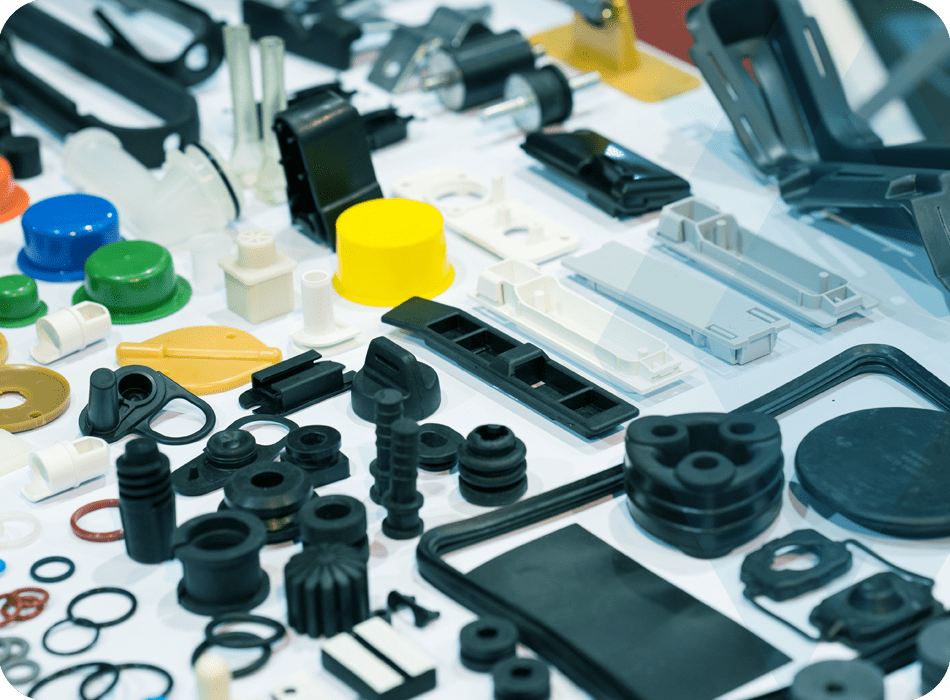

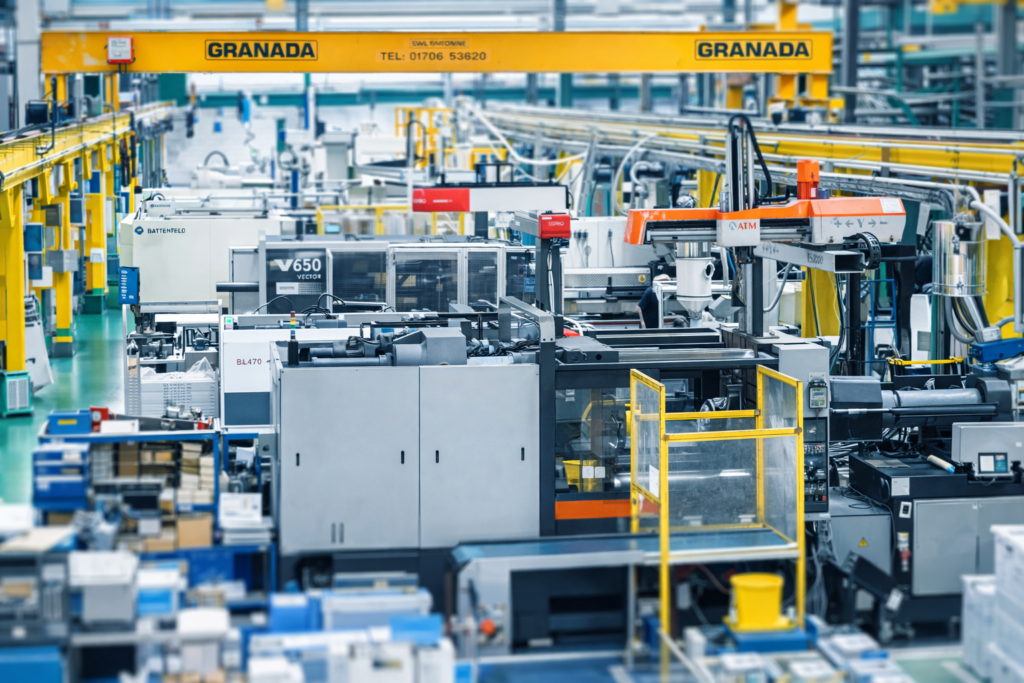

At Flambeau Europe, our injection moulding machine sizes range from 60 to 1700 tonnes. This gives us the flexibility to handle a vast spectrum of plastic parts for clients across sectors. Based in Ramsgate, Kent, our 120,000 sq/ft facility is home to one of the most diverse fleets of injection moulding machines in the UK. This wide capability allows us to support everything from intricate components to large-scale mouldings with precision, speed, and consistency.

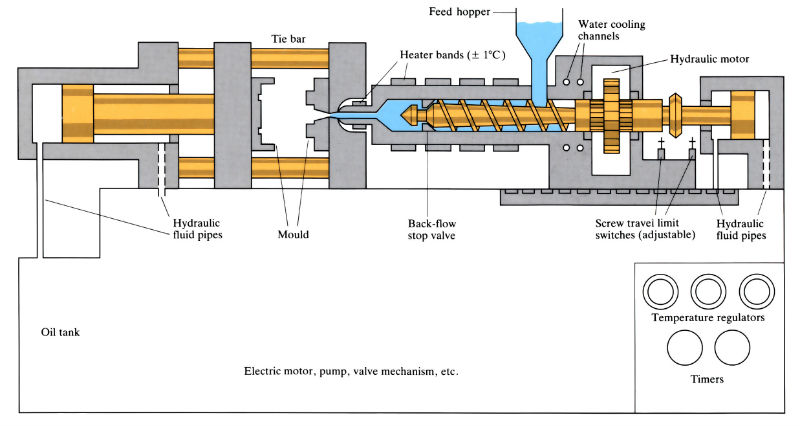

What Is Injection Moulding and How Does It Work?

Injection moulding is a highly versatile manufacturing process used to produce plastic components by injecting molten material into a mould cavity. The process involves heating plastic pellets until they melt, then injecting that molten plastic under pressure into a mould. Once the plastic cools and solidifies, the mould opens, and the finished part is ejected. This technique is ideal for high-volume production and is known for its repeatability and cost-efficiency.

Why Injection Moulding Machine Sizes Matter

The injection moulding machine size refers primarily to the clamping force it can apply — measured in tonnes. This force is crucial for keeping the mould securely closed during injection, especially when handling larger parts or high-pressure applications. Choosing the right machine size ensures the mould doesn’t warp or open under pressure, leading to a more accurate, durable product.

At Flambeau Europe, we’ve invested in a wide range of machine sizes to serve the varying needs of our clients… whether you’re producing small medical components, automotive parts, retail packaging, or large industrial housings.

Our Machine Fleet: Exploring Injection Moulding Machine Sizes from 60 to 1700 Tonnes

Let’s explore what a fleet of injection moulding machines of progressively increasing size can offer a business like Flambeau Europe. With injection moulding machine sizes ranging from 60 tonnes all the way up to 1700 tonnes, we’re able to serve clients with a huge variety of project needs, from small, intricate components to large, structural mouldings. Here’s a look at what these different machine sizes typically mean for your product:

60–150 Tonnes: Compact Precision

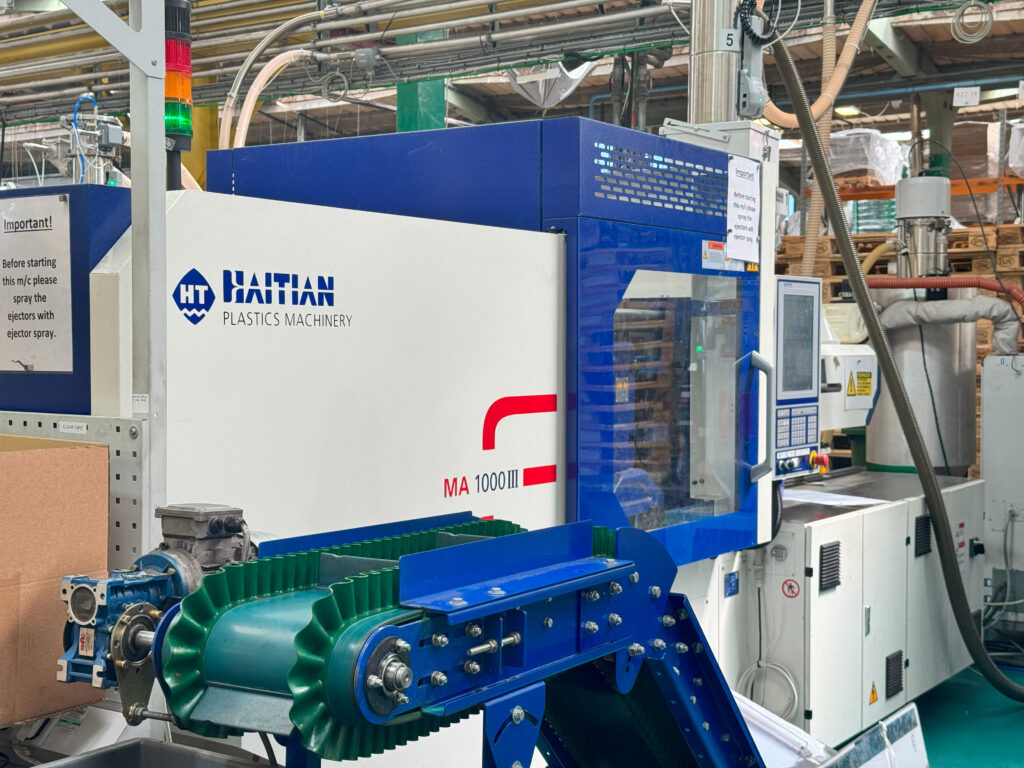

Our smallest machines, such as our new 60-tonne Haitian model, are ideal for manufacturing small plastic parts with high levels of detail and tight tolerances. These machines typically have:

- Clamping force: 60–150 tonnes

- Machine footprint: ~2.5–4m in length

- Mould weight capacity: Up to 1–1.5 tonnes

- Typical part size: Components under 150g, such as caps, clips, connectors, and precision technical items

This tonnage range is perfect for high-speed production of small items where accuracy, consistency, and fast cycle times are essential… commonly used in medical, electronics, and consumer product applications.

We recently shared a blog post all about our new 60-tonne Haitian mode, tap here to find out how it will allow us to serve our customers both current and prospective in the future in a more effective and efficient way.

200–500 Tonnes: Mid-Range Versatility

These medium-tonnage machines strike the balance between part complexity and mould size. At this scale, we can accommodate multi-cavity tools or produce larger individual components.

- Clamping force: 200–500 tonnes

- Machine footprint: ~4–6m in length

- Mould weight capacity: Up to 3–6 tonnes

- Typical part size: Items between 150g–1.5kg, including containers, handles, enclosures, and automotive components

This range is ideal for customers who need volume, flexibility, and moderate part sizes with tight quality control. These machines often serve clients in the automotive, packaging, and retail sectors.

600–1000 Tonnes: Large Part Production

As we move into larger machines, we start supporting much heavier and bulkier products.

- Clamping force: 600–1000 tonnes

- Machine footprint: ~6–8m in length

- Mould weight capacity: Up to 8–12 tonnes

- Typical part size: 1.5kg–5kg components, including panels, casings, and structural parts

These machines are designed to handle complex moulds with significant shot sizes and multiple moving parts. This is where mould cooling, cycle efficiency, and mould weight management become increasingly critical.

1200–1700 Tonnes: Maximum Scale and Strength

Our largest machines — up to 1700 tonnes — are built for high-pressure moulding of substantial parts that demand extreme rigidity and support.

- Clamping force: 1200–1700 tonnes

- Machine footprint: 8–12m+ in length

- Mould weight capacity: Up to 20 tonnes or more

- Typical part size: 5kg or more, depending on the design, including bins, pallet containers, large enclosures, and industrial components

These machines can accommodate extremely large moulds with high shot capacities, making them ideal for customers who need strength, scale, and high-performance materials. This tonnage range opens up new possibilities for heavy-duty applications in logistics, construction, automotive, and specialist technical industries.

No matter the scale, our investment in a full spectrum of injection moulding machine sizes means we always have the right machine — and the right technical expertise — for the job.

Let’s Bring Your Idea to Life

Whether you’re designing something small and precise or large and rugged, our wide range of injection moulding machine sizes means we’ve got the right setup for your job.

- Take a look at our full capabilities to see how we can support your project from start to finish.

- Check out our customer case studies to see how our machines have helped businesses like yours bring products to market.

Or if you’re already thinking ahead, get in touch with us — we’d love to hear about your next project.

We’re here to help you make it happen.