What is Lean Injection Moulding and Why It Matters for Reducing Manufacturing Waste

Manufacturing waste is a hidden cost in many production processes. From excess material usage to defective parts, waste can eat into profits and harm sustainability goals. Reducing manufacturing waste is not just an operational improvement and an environmental sustainability KPI; it’s a strategic advantage.

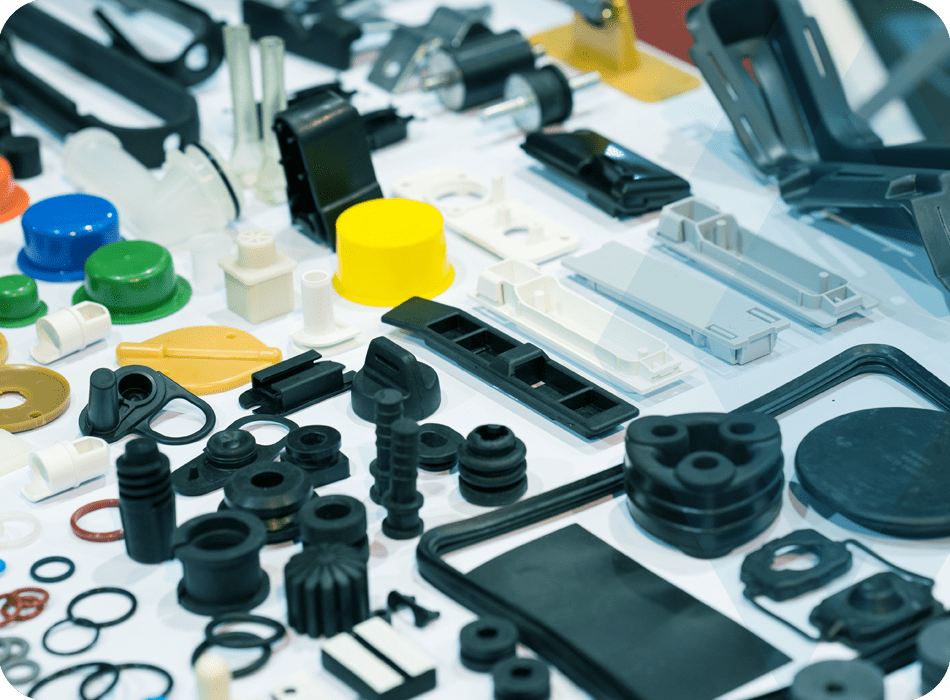

Lean injection moulding is a method that applies lean manufacturing principles to the injection moulding process. At Flambeau Europe, we specialise in producing high-quality plastic components efficiently, helping customers reduce material waste in their products and improve overall cost-effectiveness. By adopting lean techniques in our production processes, we deliver high-quality components with minimal material loss.

For projects that require precise prototyping before production, we often integrate 3D printing in product development to refine designs efficiently while keeping waste to a minimum.

Understanding Lean Principles in Manufacturing

At its core, lean manufacturing is about doing more with less. This means using fewer resources, less time, and minimal material to achieve the same—or better—output. Lean principles emphasise continuous improvement, workflow efficiency, and the elimination of any activity that doesn’t add value.

How Lean Injection Moulding Targets Material Loss

In injection moulding, waste often comes in the form of excess raw material, faulty products, or inefficient machine cycles. Lean injection moulding targets these areas by:

- Optimising cycle times to reduce idle machine hours and improve production efficiency.

- Using precise material dosing to avoid excess usage and reduce scrap.

- Implementing robust quality control to prevent defects and minimise material loss.

For customers looking for a complete end-to-end production solution, our Complete Bespoke Solutions service ensures minimal waste while producing high-quality, cost-effective components.

Common Sources of Manufacturing Waste and How to Reduce It in Injection Moulding

Even modern factories face challenges when it comes to reducing manufacturing waste. Understanding the main sources of waste is the first step toward addressing them effectively. Globally, waste generation continues to grow, and reducing material loss in production is becoming increasingly important to meet sustainability targets (UNEP Global Waste Management Outlook 2024).

Overproduction and Excess Material

Producing more parts than needed or using more material than necessary is a common source of waste. Lean injection moulding focuses on accurate production planning to prevent overproduction.

Defective Parts and Rework

Faulty components result in scrap or rework, both of which contribute to waste. By implementing lean techniques in our own production, Flambeau Europe ensures customers receive defect-free components, keeping costs low. At our facility in Ramsgate, UK, we are able to regrind and reuse the material in defective parts to reduce waste. However, the less we need to utilise this extra process, the better, since this adds additional complexity and energy use to the whole process.

Our clients also benefit from project management expertise in plastics to ensure every order is delivered on time and on budget, with minimal material waste.

Machine Downtime and Inefficiencies

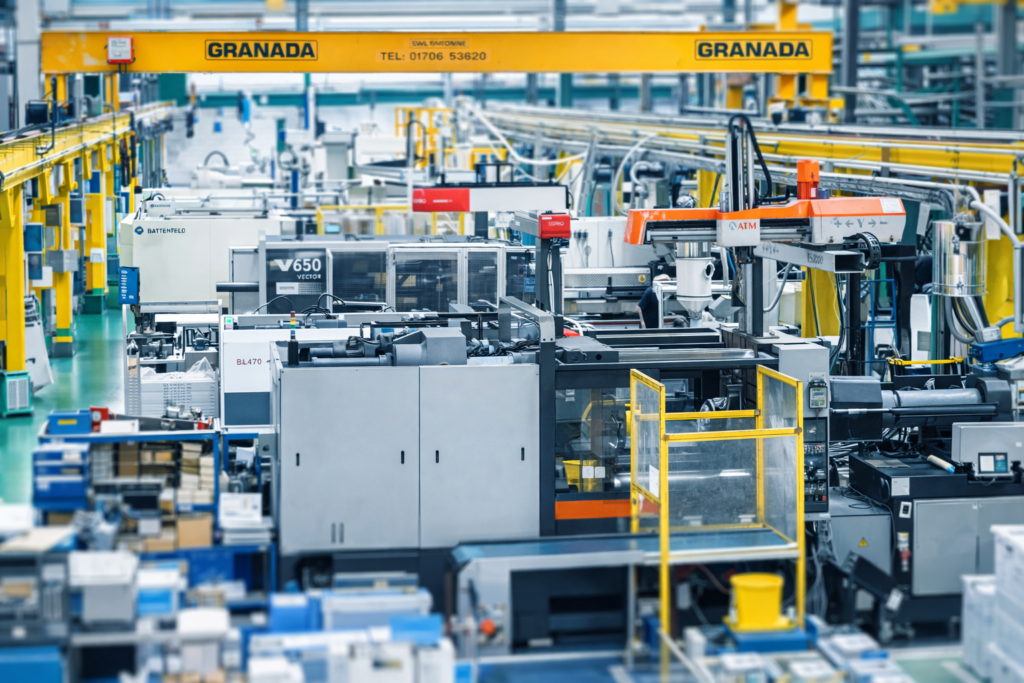

Unplanned machine stoppages, slow cycle times, or poorly maintained equipment create inefficiencies that increase waste. Lean practices emphasise preventive maintenance and efficient machine operation. At Flambeau Europe, we have a dedicated team for machine and operation maintenance who are always ready to diagnose and fix any sign of a problem before they affect manufacturing leadtimes and quality.

Learn more about how automation in injection moulding helps reduce downtime and waste while improving component consistency.

Proven Strategies for Reducing Manufacturing Waste with Lean Injection Moulding

Reducing manufacturing waste requires actionable strategies that address both process inefficiencies and material losses. At Flambeau Europe, we apply these lean injection moulding techniques directly in our production, helping customers get high-quality, cost-efficient components.

Optimising Production Cycles to Reduce Manufacturing Waste

Lean injection moulding techniques analyse and adjust cycle times to ensure every machine run is efficient. This minimises idle time and reduces energy and material consumption, lowering costs for customers.

Material Efficiency Techniques to Reduce Manufacturing Waste

Using recycled or regrind materials, optimising shot sizes, and controlling material flow ensures minimal waste without compromising product quality. Our bespoke plastic moulding process approach incorporates these strategies from design to completion, delivering cost-effective, sustainable production.

Quality Control Methods to Reduce Manufacturing Waste and Defects

Regular inspections, automated defect detection, and robust process monitoring prevent defective parts from entering production, reducing scrap and helping customers avoid unnecessary costs.

Automation and Monitoring for Waste Reduction

Smart sensors, automated controls, and real-time monitoring help detect inefficiencies instantly, allowing our production teams to maintain precision injection moulding standards. For more on modern factory innovations, see robotics in manufacturing.

The Benefits of Reducing Manufacturing Waste in Injection Moulding

Implementing lean injection moulding techniques in production doesn’t just reduce waste—it brings measurable benefits for customers.

Cost Savings and Profitability

Less material waste, fewer defects, and reduced downtime directly translate into lower production costs, improving profitability for our customers’ products.

Sustainability and Environmental Impact

Reducing waste also supports sustainability goals. In the UK, official statistics show that waste management and material efficiency are key priorities for manufacturers seeking to lower their environmental footprint (UK Statistics on Waste – DEFRA). Less scrap, lower energy usage, and minimal material overproduction help make products more environmentally friendly.

Enhanced Efficiency and Consistency

Lean processes create a more predictable, reliable production system. This means faster cycle times, consistent product quality, and improved delivery performance for customers.

For insights into broader industry trends, see our post on reshoring production in UK manufacturing.

How Flambeau Europe Helps Customers Reduce Material Waste and Costs

At Flambeau Europe, we apply lean injection moulding principles directly in our production to deliver high-quality, cost-effective components. By optimising cycles, reducing scrap, and maintaining strict quality control, we help customers reduce material waste in their products while lowering overall costs.

Conducting a Manufacturing Waste Audit in Production

We analyse every stage of production to minimise material loss and maintain tight tolerances, ensuring customers get the highest quality output and efficiency.

Training Our Teams for Lean Manufacturing Excellence

Our teams are trained in lean manufacturing techniques, ensuring every component produced meets quality standards with minimal waste. Additionally, our maintenance team dedicate their time to ensuring all of our machines and operations are at full capacity and efficiency, implementing preventative measures before issues can become problems.

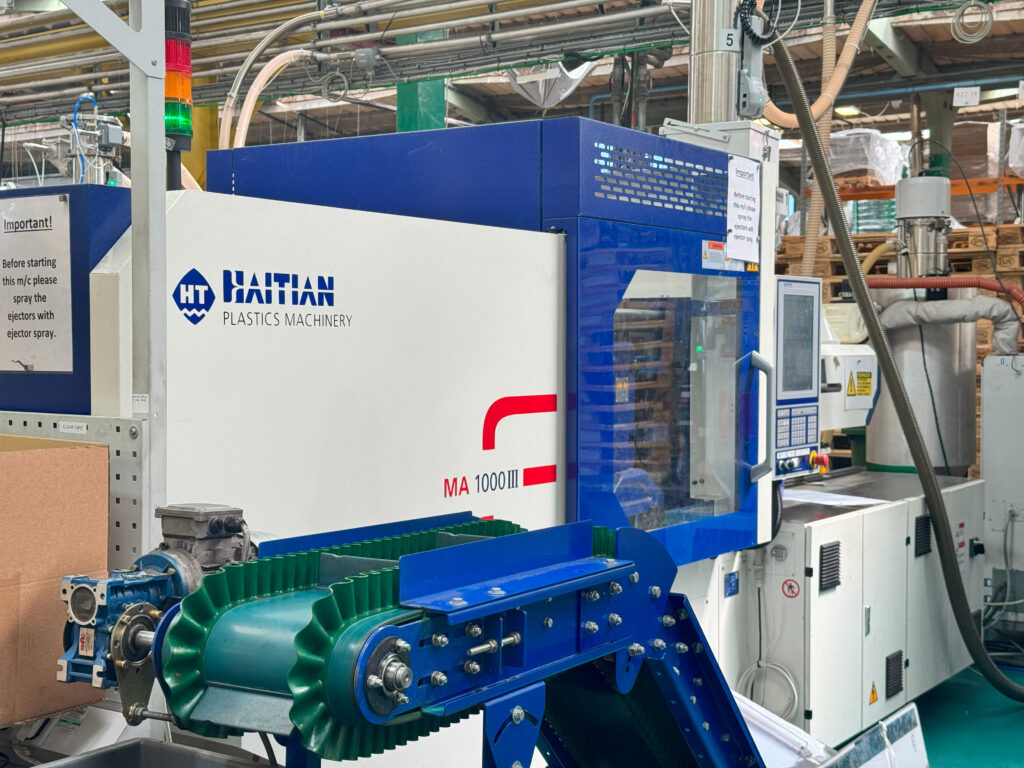

Upgrading Equipment for Precision Production

We invest in advanced injection moulding machines and monitoring systems to maintain precision, cut waste, and reduce costs for customers. It is paramount that we stay at the forefront of manufacturing and injection moulding technology as it progresses. New AI systems and advanced technologies within machines allow us to more effectively execute our lean manufacturing mission.

You can learn more about our machine investments throughout the year of 2025 here.

Continuous Improvement and Monitoring

Lean is an ongoing process. Continuous optimisation in our factories ensures customers benefit from consistent quality and minimal material waste. Regular, consistent team huddles ensure an open communication loop that continuously improves our manufacturing efficiency and output.

Conclusion

Reducing manufacturing waste is essential for controlling costs, improving sustainability, and delivering consistent product quality. At Flambeau Europe, we integrate lean injection moulding directly into our production, helping customers reduce material waste, lower costs, and receive high-quality components efficiently. It is these sorts of processes that led us to be awarded the Project Management of the Year award from Makita in 2024, having worked closely to ensure efficiency and sustainability for their UK packaging operations!

Want to reduce waste and production costs for your products? Work with Flambeau Europe and take advantage of our lean injection moulding expertise to get high-quality, cost-effective components for your projects.