Project Management in Injection Moulding: Why It Matters

Effective project management in injection moulding is the backbone of delivering high-quality plastic components on time and within budget. Furthermore, at Flambeau Europe, we understand that each project is more than just a manufacturing task — it’s a collaboration with our clients, requiring precision, foresight, and proactive problem-solving.

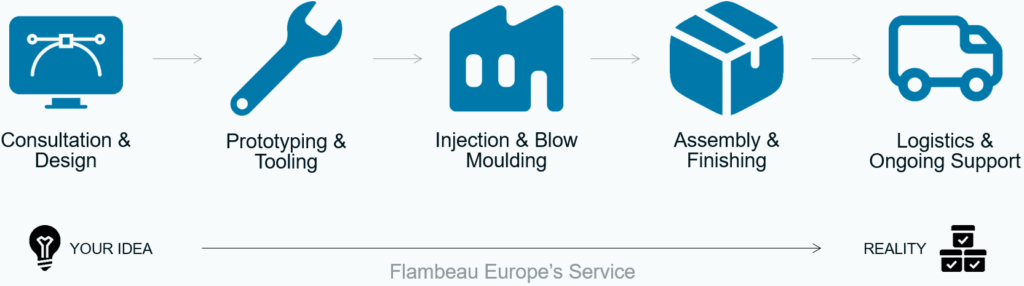

From the moment a project begins, we coordinate every stage: from concept discussions and tooling preparation to production, quality assurance, and final delivery. This approach ensures that potential challenges are identified early, timelines are maintained, and clients can trust their projects will be handled efficiently.

Furthermore, our project management philosophy is rooted in Flambeau’s core values — Family, Teamwork, Integrity, Knowledge, Leadership, and Excellence — which guide our interactions and decision-making. These values ensure we approach every project with care and commitment, treating clients like part of our extended team. Learn more about our values here.

By integrating these principles with technical expertise, we consistently deliver projects that meet client expectations and often exceed them.

The Foundation: Building Projects on Shared Values

Our company values are more than aspirational statements — they are the foundation for every project we manage.

- Family & Teamwork: Just as strong families foster responsibility and collaboration, our teams work together to ensure clients’ needs are prioritised. We encourage open dialogue and actively involve clients in key decisions. By aligning our teams and clients on shared goals, we create a seamless project experience.

- Integrity & Excellence: Ethical practices and accountability guide every stage of a project. We communicate openly about progress, potential risks, and solutions. Our commitment to excellence ensures that every product meets stringent quality standards, while our transparent approach builds trust with clients.

- Knowledge & Leadership: Flambeau’s project teams bring decades of experience and continually expand their expertise. This enables us to anticipate challenges, offer valuable recommendations, and guide projects efficiently. Leadership at every level ensures the team works cohesively, solving problems proactively rather than reactively.

By embedding these values into project management, we don’t just deliver components — we deliver confidence, reliability, and consistent quality.

Project Management in Injection Moulding: Collaboration Across the Supply Chain

A successful injection moulding project relies on more than individual technical capability. It requires collaboration across the entire supply chain.

Our approach emphasises understanding not only our role but also, importantly, the interconnected roles of tooling suppliers, logistics partners, and, crucially, our clients. For example, by reviewing tooling plans with suppliers and discussing timing with logistics teams early in the process, we can prevent delays before production begins.

Additionally, this collaborative mindset allows us to identify efficiencies in processes that might otherwise go unnoticed. Perhaps a minor change to mould design reduces cycle time, or adjusting delivery schedules streamlines workflow across partners.

This proactive coordination distinguishes Flambeau from typical injection moulding suppliers. We don’t just manufacture parts — we optimise the efficiency of the entire project, ensuring superior results for our clients.

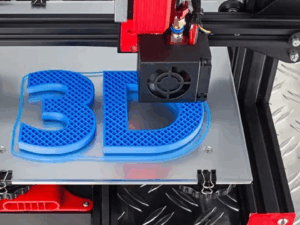

See how automation in injection moulding drives innovation at Flambeau Europe

Learn about robotics trends in modern manufacturing.

Project Management in Injection Moulding: Systems, Data, and Continuous Improvement

Advanced systems and data analysis are essential for high-performance project management in injection moulding. At Flambeau, we leverage technology to monitor every aspect of production.

From tracking machine utilisation to monitoring quality metrics, our systems allow us to detect potential issues early. For instance, if a variation in a moulded component is identified, adjustments can be made immediately to prevent further defects.

Moreover, we adopt an iterative improvement approach. Each project provides insights that improve future workflows, optimise cycle times, and reduce waste. By combining technology, data, and experience, we continually refine our processes, delivering projects that are more efficient and reliable with every iteration.

Learn more about optimising high-precision injection moulding.

Project Management in Injection Moulding: Communication Builds Trust

Clear communication is the cornerstone of successful project management. At Flambeau, we prioritise transparent and consistent messaging throughout the project lifecycle.

This includes:

- Frequent updates on progress, timelines, and any potential risks.

- Proactive problem-solving discussions, ensuring clients are aware of issues before they become delays.

- Open channels for client feedback, enabling quick decisions and realignment where necessary.

By fostering clear communication, we maintain trust and accountability. Clients know exactly where their project stands, reducing uncertainty and enabling smooth collaboration. This proactive approach transforms complex projects into predictable, manageable processes.

Project Management in Injection Moulding: Becoming More Than a Supplier

Through expert project management, Flambeau Europe becomes more than just a component manufacturer — we are a turnkey partner.

Our value-added services include:

- Tooling and design guidance to ensure optimal production outcomes

- Detailed production planning and scheduling to meet timelines

- Logistics and packaging solutions for safe and efficient delivery

- Post-production finishing and assembly services

By integrating these services, we help clients streamline their operations and reduce risk. Our expertise ensures that every project delivers maximum value, not only meeting expectations but often exceeding them.

Discover our Complete Bespoke Solutions

Learn about collaborative robots in manufacturing.

Project Management in Injection Moulding: Strengthening UK Manufacturing

Professional project management doesn’t just benefit individual clients — it also strengthens the broader UK manufacturing sector.

By delivering projects efficiently, maintaining quality, and optimising workflows, Flambeau Europe supports reshoring and robust local supply chains. Shorter lead times and dependable partners mean UK businesses can respond more quickly to market demands and invest in innovation.

This demonstrates how expert project management in injection moulding contributes to both customer success and the long-term growth of the UK manufacturing industry.

Read more about trends and innovations in UK plastic manufacturing.

Conclusion: Partner With a Team That Cares

Project management in injection moulding at Flambeau Europe is more than scheduling and oversight — it is a holistic approach to delivering value. By combining expertise, technology, and open communication, we ensure projects are delivered on time, on budget, and to the highest standards.

Ultimately, partnering with Flambeau means gaining more than a supplier. You gain a trusted ally committed to your success, every step of the way.