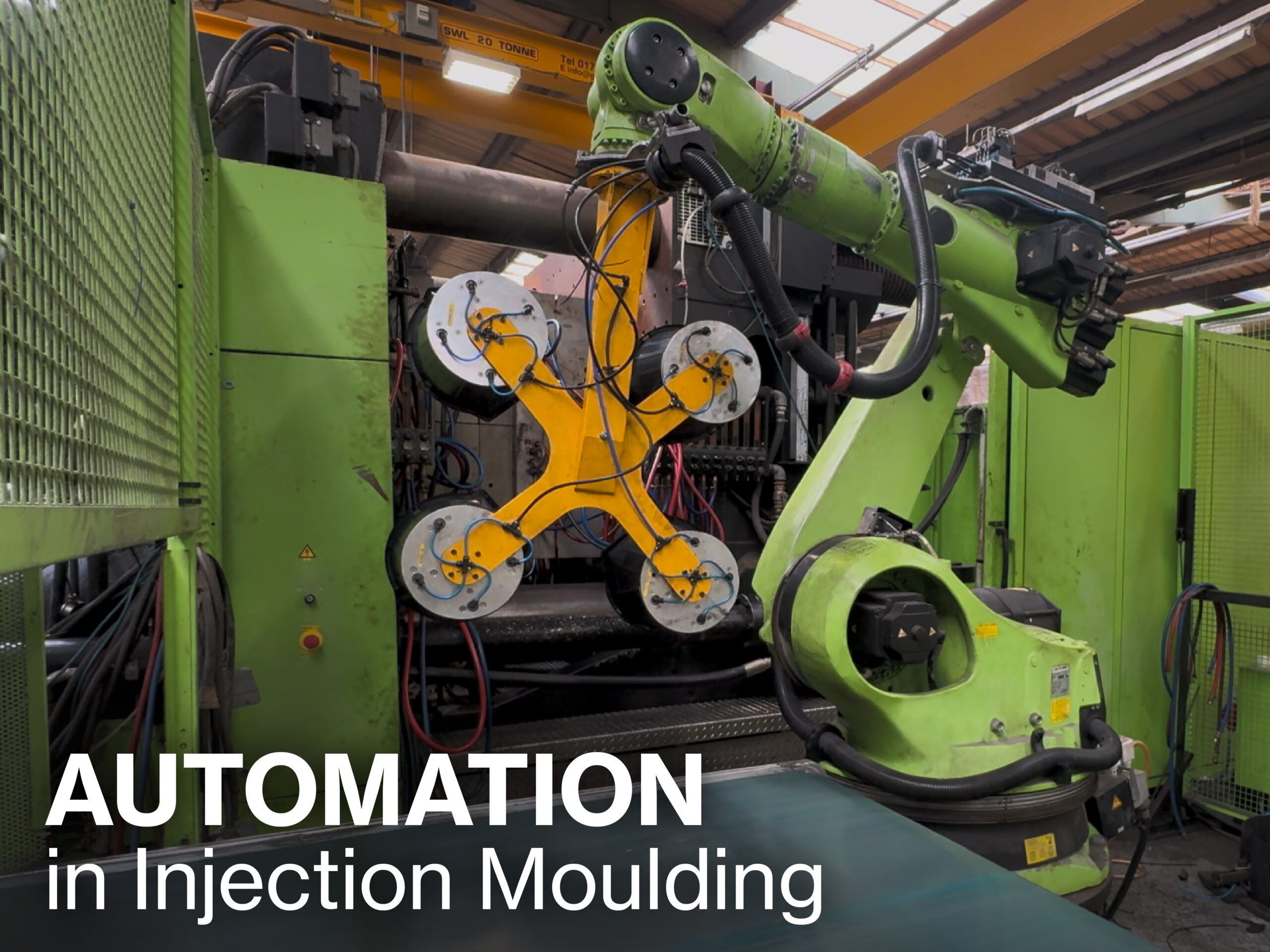

Automation in injection moulding is transforming the plastics manufacturing industry. At Flambeau Europe, we’re proud to be leading that evolution. With over 25 years of operations in the UK and a global history dating back to 1947, we’ve seen firsthand how technology has progressed. Today, we are leveraging cutting-edge automation to streamline our manufacturing processes, enhance product quality, and create more value for our customers.

Learn more about our company history.

What Is Automation in Injection Moulding?

At its core, automation in injection moulding refers to the integration of technologies, such as robotics, conveyor systems, and material handling automation, into the production cycle. These systems work seamlessly to reduce manual intervention, improve consistency, and increase output.

According to a 2024 whitepaper by OGM, fully automated injection moulding systems can reduce labour costs by up to 30% while achieving cycle time reductions of 15–25%. Moreover, automation significantly lowers the margin for error, making it essential for high-volume, precision-critical parts.

How We’re Using Automation in Injection Moulding at Flambeau Europe

At Flambeau, automation is not just a buzzword—it’s built into our day-to-day operations across several key stages:

🔹 Automated Material Feeding

Our plant is equipped with automated material sourcing from silos directly to injection moulding machines via precision-controlled hoppers. This ensures accurate, uninterrupted material delivery, reducing downtime and waste.

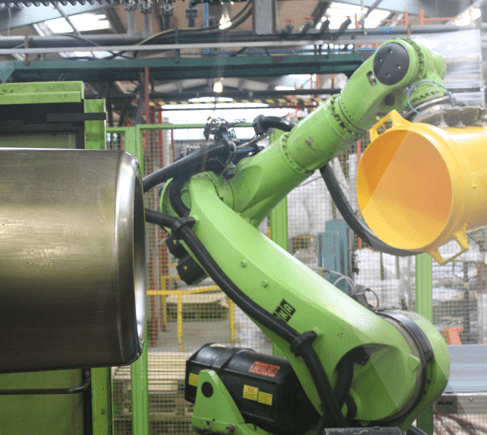

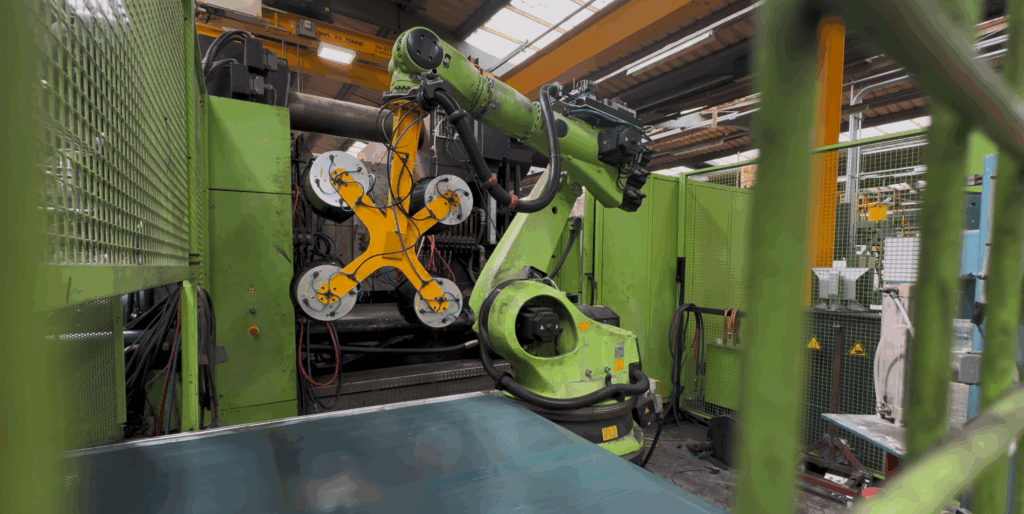

🔹 Robotic Part Removal

Once moulding is complete, robotic arms safely and precisely extract the components, minimising risk of damage and speeding up production. This is particularly beneficial for complex or delicate parts.

🔹 Conveyor Systems for Movement

Our automated conveyor belts efficiently transfer freshly moulded parts to their next processing station—whether that’s inspection, assembly, or packing—without the need for manual handling.

🔹 Automated Wrapping and Palletisation

Finally, we use automatic wrapping systems to prepare finished products for shipment, ensuring consistency, reducing manual labour, and improving packaging speed.

These systems work in unison to create a high-efficiency production line that supports our reputation for reliability and quality.

Empowering People, Not Replacing Them

One of the biggest misconceptions about automation is that it eliminates jobs. In reality, we see it as a way to empower our people.

Automation takes on repetitive, physically demanding tasks, freeing up our skilled team to focus on more strategic, creative, and quality-focused roles. It also opens up new opportunities, such as robot maintenance technicians, automation engineers, and systems analysts.

Rather than replacing jobs, automation supercharges them, allowing our staff to work smarter, not harder.

Better for Our Customers, Better for Their Products

With the help of automation, we’re able to deliver:

- Greater consistency across product batches

- Faster turnaround times on orders

- Lower rejection rates due to improved precision

- Enhanced scalability for large or complex projects

This all contributes to stronger outcomes for our clients, whether they’re developing new products or scaling up production. Our Complete Bespoke Solutions offering further enhances this, allowing us to collaborate closely with customers to tailor automation-enhanced processes to their exact needs.

The Future of Automation in Injection Moulding

Automation is not a one-time investment—it’s a continuous journey. At Flambeau Europe, we’re constantly exploring new ways to integrate smart technology into our operations, aligning with the principles of Industry 4.0.

From data-driven monitoring systems to intelligent robotics, we remain committed to staying at the cutting edge. But the next leap forward? Artificial Intelligence (AI).

We’re already looking at how AI can be harnessed to further optimise our processes. Such as predictive maintenance, real-time quality control, and even adaptive moulding adjustments during production. The rise of AI presents exciting opportunities to boost efficiency, reduce downtime, and make smarter, faster decisions across our manufacturing environment.

As these technologies continue to evolve, we’re preparing to embrace them in our factories, future-proofing our operations and ensuring we continue to deliver exceptional results for our customers.

Let’s Build the Future Together

As automation in injection moulding continues to evolve, Flambeau Europe remains focused on delivering smarter, faster, and more reliable solutions for our customers.

Want to find out how automation could benefit your next project? Get in touch or explore our complete range of bespoke services.