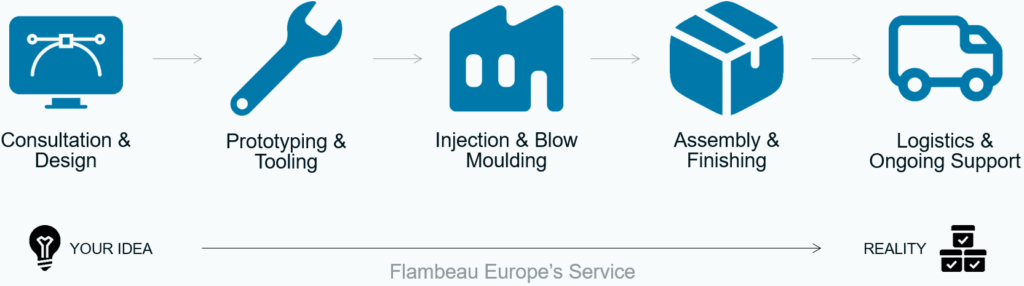

Modern manufacturing demands more than simply producing parts. Businesses today need reliability, efficiency, and supply chain confidence. Yet many suppliers still operate within narrow production roles, leaving customers to coordinate multiple vendors, manage handovers, and absorb the risks that come with fragmented delivery. An end-to-end injection moulding approach removes that complexity. By integrating design, tooling, moulding, assembly, and logistics, manufacturers can streamline workflows, reduce risk, and create a more dependable supply chain.

At Flambeau Europe, our end-to-end injection moulding capability goes beyond production. We integrate into our customers’ operations to deliver complete solutions that support performance, continuity, and long-term success.

What End-to-End Injection Moulding Really Means

End-to-end injection moulding is not simply about offering multiple services. It is about aligning every stage of production to deliver consistent outcomes.

Beyond production: delivering complete solutions

Traditional moulding services focus on output. In contrast, an integrated approach ensures every stage supports performance, compliance, and efficiency.

Reducing handovers and supply chain friction

Each additional supplier introduces risk. By consolidating services under one partner, businesses reduce delays, miscommunication, and accountability gaps.

Supporting the full product lifecycle

From initial concept to ongoing production, an end-to-end model provides continuity that protects quality and long-term performance.

This approach underpins Flambeau’s Complete Bespoke Solutions, where integration replaces fragmentation.

Stage 1: Design & Engineering Optimisation

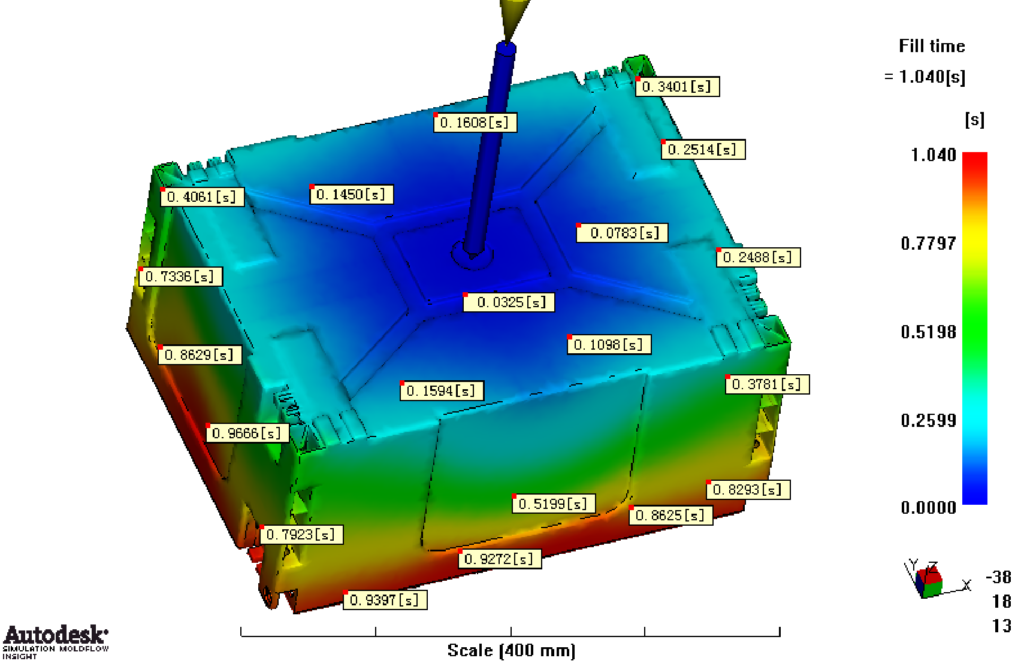

The success of any moulded component begins long before tooling is cut.

Designing for manufacturability and performance

Early engineering collaboration ensures parts are optimised for mould flow, strength, and production efficiency.

Preventing costly issues before tooling begins

Small design decisions can create high downstream costs. Early refinement helps prevent warping, weak points, or tooling complications.

Material selection and compliance considerations

Selecting the correct material affects durability, regulatory compliance, and long-term performance.

Our Bespoke Plastic Moulding Process demonstrates how early collaboration improves outcomes.

Value: Early optimisation reduces delays, waste, and rework.

Stage 2: Tooling Strategy & Performance

Tooling is a long-term investment. Its design and management determine consistency and repeatability.

Tool design aligned with production efficiency

Tooling must support cycle time efficiency and product consistency.

Extending tool life and maintaining performance

Ongoing monitoring and optimisation help preserve tool integrity and prevent downtime.

Managing mould transfers and maintenance

Customers trust Flambeau with tooling transfers because we prioritise performance continuity.

Value: Strong tooling strategy protects investment and ensures repeatable output.

Stage 3: Precision Injection Moulding

At the core of end-to-end injection moulding is process control.

Process control and repeatability

Precision settings and monitoring ensure consistent results across production runs.

Maintaining quality across batches

Consistency protects downstream assembly, compliance, and customer satisfaction.

Scaling production with confidence

Reliable processes allow production to scale without compromising quality.

Our expertise in high-precision injection moulding supports complex, performance-critical components.

Value: Consistency reduces operational risk and protects supply continuity.

Stage 4: Assembly & Value-Added Services

Integrated assembly reduces supplier complexity and improves efficiency.

Reducing supplier complexity

Combining moulding and assembly eliminates additional handling stages.

Improving efficiency through integrated assembly

Pre-assembled components reduce labour and processing time for customers.

Supporting multi-component product delivery

Integrated production ensures compatibility and quality across components.

Value: Streamlined delivery simplifies procurement and improves operational efficiency.

Stage 5: Logistics & Supply Chain Support

Production is only complete when products arrive where and when they are needed.

Coordinating delivery schedules and inventory needs

We work closely with customers to align delivery schedules with production and demand cycles.

Supporting just-in-time supply models

Reliable UK-based logistics support efficient inventory management.

UK distribution for reliability and speed

Domestic production and distribution reduce delays and supply uncertainty.

This integrated model supports the supply chain resilience discussed in How Flambeau Ensures Supply Chain Resilience through Local Manufacturing.

Value: Reliable delivery strengthens planning and operational confidence.

Why Integration Reduces Risk and Cost

Fragmented supply chains create hidden costs. End-to-end injection moulding removes unnecessary complexity.

Fewer suppliers, fewer delays

Consolidation reduces coordination challenges and scheduling conflicts.

Improved communication and accountability

A single partner ensures clarity and faster decision-making.

Lower total cost of ownership

Integration reduces administrative burden, logistics costs, and disruption risk.

As explored in Cost Savings with UK Injection Moulders, the true value extends beyond unit price.

A Partnership Approach, Not a Transaction

End-to-end injection moulding is most effective when delivered through partnership.

Integrating into customer operations

We align production with customer demand, timelines, and regulatory requirements.

Supporting long-term product success

Retained knowledge improves efficiency over time.

Solving problems, not taking orders

We work proactively to prevent issues and optimise performance.

This partnership mindset defines Flambeau’s bespoke approach.

Why Customers Choose Flambeau’s End-to-End Injection Moulding

Customers rely on Flambeau because our integrated approach delivers:

- Consistent quality and traceability

- Reduced supply chain risk

- Faster communication and responsiveness

- Lifecycle support from concept to delivery

- Long-term manufacturing continuity

Our Ramsgate manufacturing base combines technical capability with stability and retained expertise, ensuring dependable performance over time.

From Concept to Continuity

End-to-end injection moulding simplifies manufacturing by aligning every stage of production into one cohesive workflow. By reducing handovers, improving communication, and supporting the full product lifecycle, businesses gain greater control, reliability, and long-term confidence.

At Flambeau Europe, our integrated approach transforms manufacturing from a transactional process into a partnership built on performance and continuity. From design and tooling through to moulding, assembly, and logistics, we deliver end-to-end injection moulding that supports your business at every stage.

Contact Flambeau Europe

If you are looking for an end-to-end injection moulding partner that reduces complexity, improves reliability, and supports long-term success, our team is ready to help.

👉 Contact us today to discuss your project requirements and explore how our integrated approach can support your manufacturing needs.