From Concept to Market-Ready Solution: Flambeau Europe’s Bespoke Plastic Moulding Process

Bringing a plastic product from idea to finished solution requires precision, expertise, and a partner who can deliver every step with confidence. Flambeau Europe’s bespoke plastic moulding process transforms concepts into high-quality, market-ready components tailored to your exact specifications.

With decades of experience, advanced CAD and tooling capabilities, and in-house assembly and finishing operations, we provide end-to-end solutions that reduce lead times, streamline supply chains, and ensure products meet the highest standards of performance and durability. Whether for complex engineering parts or high-volume retail components, our approach combines innovation, quality, and customer-focused service at every stage.

Understanding Bespoke Plastic Moulding

Bespoke plastic moulding is more than just creating a component; it’s a tailored approach that transforms specific requirements into functional, high-quality products. Unlike standard moulding processes, which often rely on off-the-shelf designs, bespoke moulding allows for full customisation in materials, design, and production methods. This flexibility ensures optimal performance, cost efficiency, and alignment with your business needs.

The Flambeau Approach: Our Bespoke Plastic Moulding Process

Consultation & Design for Bespoke Plastic Products

At Flambeau, we turn ideas into viable plastic product concepts through expert design input, engineering insight, and material guidance.

- Collaborative product development tailored to customer goals and technical requirements

- Technical solution specification, including product design for manufacture

- CAD design support (Unigraphics, Catia, SolidWorks) with MoldFlow analysis for optimal outcomes (learn more about material selection)

- Expert material selection based on performance, sustainability, and cost needs

- Early-stage project management to align feasibility, tooling, and optimisation

We help de-risk your project from the very beginning, ensuring designs are functional, cost-effective, and production-ready.

Prototyping and Tooling for Custom Plastic Parts

Bringing designs to life is the next crucial step. Flambeau uses rapid prototyping and precision tooling to validate your product before full-scale production.

- In-house 3D printing for proof-of-concept and fast, cost-effective prototypes

- Tool design, sourcing, and manufacturing tailored to project volume and material (see how we deliver tailored solutions)

- Prototype runs and sampling to ensure readiness for production

- Quality validation to confirm parts meet customer expectations (machine capabilities explained)

- Ongoing optimisation of tooling for performance, quality, and repeatability

We help customers move from concept to confident production with tools engineered to perform —from first run to final unit.

Production and Quality Assurance of Bespoke Plastic Components

Our advanced injection moulding machinery and automation capabilities allow Flambeau to deliver consistent, high-quality plastic components at scale.

- 16 machines ranging from 60 to 1700 tons of clamp force

- Capable of producing both complex and large-volume components

- Real-time production tracking via Enterprise IQ software

- Wide material compatibility, including PP, HDPE, LDPE, ABS, PA6, PA66, PC

- Accredited to ISO 9001, ISO 14001 & TS 16949

Trusted by global brands, Flambeau ensures reliable, repeatable parts —from tight-tolerance engineering components to robust retail solutions.

Assembly and Secondary Operations

Flambeau offers a range of in-house operations that turn moulded parts into complete, finished products —ready for market.

- Component assembly and integration to customer specification

- Over-moulding, trimming, drilling, and other finishing processes

- In-line labelling, handling, automation design, and quality checks

- Seamless flow from production to final assembly on-site

Our flexible post-moulding operations help customers reduce lead times, simplify their supply chains, and lower total production costs.

Final Product Delivery

We manage product fulfilment, distribution, and aftercare —giving customers peace of mind long after production.

- Warehousing, forecasting, pick & pack, and distribution across the UK and Europe (learn about navigating supply chain disruptions)

- Integrated EDI systems for ordering, invoicing (multi-currency), and barcode labelling

- Process maintenance to guarantee supply consistency and reliability

- Dedicated customer, engineering, and technical support teams

- Ongoing support for product updates, tooling optimisation, and supply chain continuity

We don’t just manufacture —we ensure your product reaches market smoothly and continues to evolve with your needs.

Case Studies: Successful Bespoke Plastic Moulding Projects

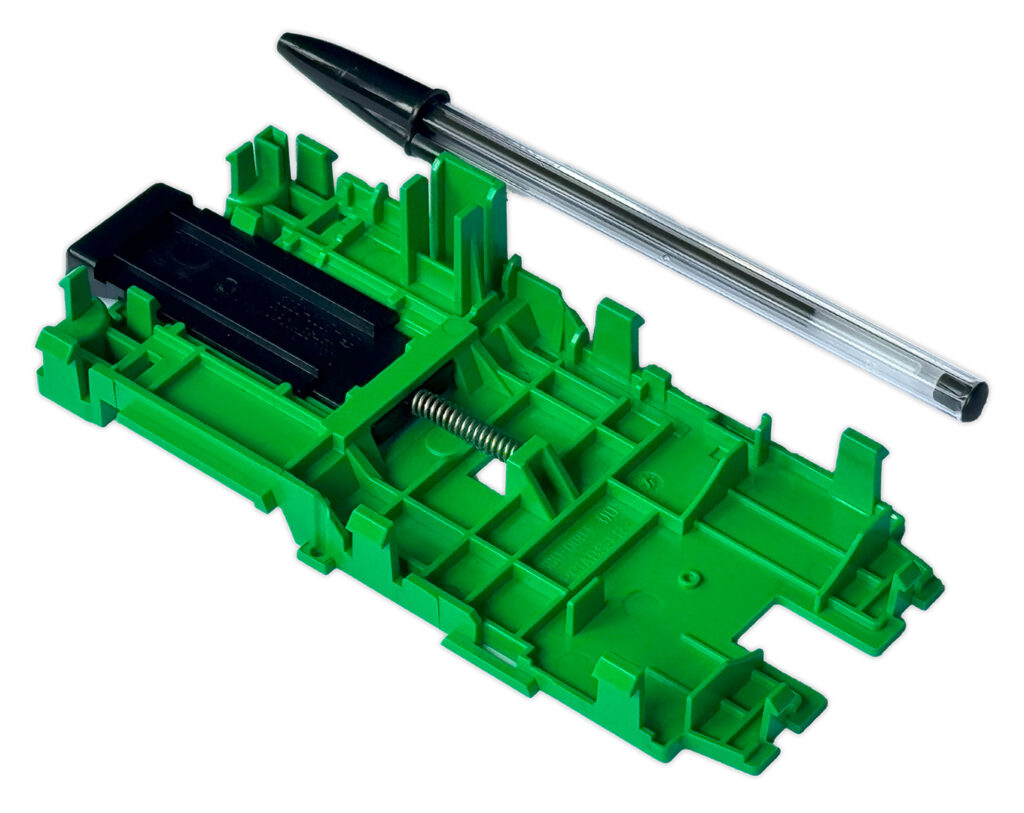

Makita

Flambeau Europe partnered with Makita, a globally recognised power tool brand, to reshape its European supply chain. Previously, empty connector cases were produced in China and Romania before being shipped to the UK, creating high costs, lengthy lead times, and higher rejection rates due to transit damage. By reshoring production to Flambeau’s UK facility, Makita achieved a leaner, more resilient supply chain, benefiting from Just-In-Time manufacturing, reduced warehousing, faster turnaround, and dramatically lower product damage during transport.

Supporting this partnership, Flambeau invested over £2 million in new injection moulding machines, a dedicated production cell, and advanced quality systems, ensuring consistent, high-quality outputs while driving efficiency and cost savings. This collaboration has not only strengthened Makita’s operations in the UK but also earned Flambeau the 2024 Makita Supplier Award. Read the full Makita case study here. For more on reshoring benefits, see Cost Savings with UK Injection Moulders and UK Injection Moulding and the Reshoring Revival.

Volution

Flambeau Europe has partnered with Volution Group plc for nearly four decades, supporting the design, production, and delivery of high-performance, injection moulded components for residential and commercial ventilation systems. By integrating sustainable practices, including the use of post-consumer recycled polymers, Flambeau helps Volution achieve ambitious environmental targets while maintaining regulatory compliance and mechanical performance. This long-standing partnership demonstrates how bespoke plastic moulding can scale with growth, ensuring product reliability, efficiency, and reduced environmental impact.

Through modern injection moulding machinery, custom tooling, and flexible assembly and logistics solutions, Flambeau enables Volution to innovate rapidly, meet increasing global demand, and optimise production processes. Read the full Volution case study here to learn how our sustainable injection moulding partnership supports low-impact manufacturing and business growth across the UK and Europe. Learn more about our sustainable plastic manufacturing policy.

Why Choose Flambeau Europe for Bespoke Plastic Moulding?

Flambeau Europe’s expertise in bespoke plastic moulding spans decades, industries, and applications. Clients choose us because we combine:

- Deep engineering knowledge and design capability

- Advanced production facilities and quality assurance

- Commitment to innovation, sustainability, and customer satisfaction

Our end-to-end service ensures that every project is handled efficiently, reliably, and with the highest standards of quality. Learn more about our UK-based injection moulding company.

Conclusion

From the first concept sketches to the final delivered product, Flambeau Europe’s bespoke plastic moulding process provides a seamless, reliable path to market-ready solutions. By combining expert design, precision tooling, advanced production, and in-house assembly, we give our clients confidence that their projects will meet expectations —on time, on budget, and to exacting standards.

If you’re looking for a partner who can bring your plastic product ideas to life, Flambeau Europe is ready to help. Contact us or request a quote for your next plastic product project.