Looking for the best UK-based injection moulding companies in 2025? Selecting the right manufacturing partner is about more than just price; it’s about reliability, quality, and the ability to turn your product ideas into reality efficiently. With so many options available, understanding what sets top-tier companies apart is essential for ensuring your projects succeed.

Injection moulding is a cornerstone of modern manufacturing, powering everything from consumer products to industrial components. But working with the wrong partner can lead to delays, cost overruns, and quality issues. That’s why choosing an experienced, capable, and responsive UK-based injection moulder is crucial for protecting your investment and maximising your product’s potential.

Why Choosing the Right Injection Moulding Partner Matters

Finding the right partner can have a significant impact on your business outcomes:

- Minimising Risk: Experienced manufacturers help prevent design flaws, production errors, and supply chain disruptions, reducing costly setbacks.

- Maximising ROI: A skilled partner optimises material selection, tooling, and production processes to deliver consistent, high-quality parts at scale, ensuring you get the most value from your investment.

- Innovation Support: Top UK-based injection moulders offer expertise in design, rapid prototyping, and advanced manufacturing techniques, helping bring complex product ideas to life.

- Scalability and Flexibility: The right partner can adapt to changing volumes, material requirements, or product designs, giving you confidence as your business grows.

- Quality and Compliance: ISO-certified manufacturers maintain rigorous standards, ensuring your components meet regulatory and performance requirements across industries.

In this article, we explore the best UK-based injection moulding companies in 2025, highlighting their capabilities, market focus, and real-world successes, so you can make an informed decision about your manufacturing partner.

1. Flambeau Europe

Overview

Of course, we’re going to put ourselves at number one — but hear us out! Flambeau Europe isn’t just any UK-based injection moulding company; it’s a versatile, full-service partner capable of taking projects from concept to market with precision, reliability, and scale. Backed by global parent company Flambeau Inc., it offers end-to-end support for customers of all sizes, from initial design and tooling through to full-scale production, assembly, and distribution.

Capabilities

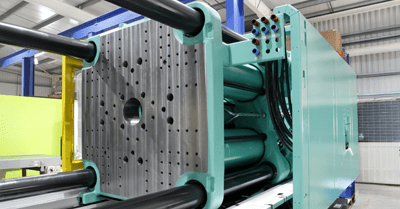

- Injection Moulding Fleet: 16 machines ranging from 60 to 1700 tonnes, capable of producing both small, intricate components and large-volume industrial parts.

- Materials Expertise: Wide compatibility, including PP, HDPE, LDPE, ABS, PA6, PA66, PC, and sustainable/recycled polymers.

- Full-Service Manufacturing: Tooling, assembly, finishing, labelling, automation, and in-line quality checks.

- Flexible Production: Small-batch prototyping, rapid tooling, and high-volume runs — ideal for industries from medical to retail.

Strengths

- ISO-Certified Quality: Accredited to ISO 9001, ISO 14001, and TS 16949, guaranteeing consistent, reliable production.

- Global Support: Leverages parent company Flambeau Inc.’s resources for technical guidance, supply chain support, and international market insight.

- Scalable Solutions: From single prototypes to full-scale production, Flambeau Europe adapts to client needs while maintaining precision and efficiency.

- Customer-Centric Approach: Technical collaboration at every stage, with dedicated engineering, operations, and quality teams ensuring seamless delivery.

Case Studies: Real-World Impact

- Makita: Facing long, complex supply chains from China and Romania, Makita reshored its connector case production to the UK with Flambeau Europe. By establishing a dedicated manufacturing cell and investing over £2 million in new injection moulding machinery, Flambeau delivered:

- Faster, Just-In-Time lead times — orders placed one day could be delivered the next.

- Reduced warehousing and transport costs.

- Dramatically lower rejection rates due to minimised transit damage.

- High-quality, consistent parts that met Makita’s rigorous engineering standards.

This partnership not only improved operational efficiency but also earned Flambeau Europe the 2024 Makita Supplier Award. Read the full Makita case study.

- Volution Group: For nearly 40 years, Flambeau Europe has supported Volution, a global leader in ventilation products, by producing precision injection-moulded components from both virgin and post-consumer recycled polymers. Key outcomes include:

- Integration of high percentages of recycled plastic without compromising mechanical or fire-resistance performance.

- Rapid prototyping and scalable production enable Volution to efficiently expand into new markets.

- Lean, low-impact manufacturing aligned with Volution’s sustainability goals, helping achieve 78% recycled content across products.

- Consistent, regulation-compliant components for residential and commercial ventilation systems across multiple countries.

This partnership demonstrates how sustainable, high-performance plastic manufacturing can scale globally. Discover the Volution story.

Why Choose Flambeau Europe

Flambeau Europe combines decades of expertise, cutting-edge technology, and a customer-first mindset. By offering comprehensive bespoke solutions, scalable capabilities, and proven results in diverse industries such as automotive, medical, and consumer products, Flambeau stands out as a leading choice and one of the best UK injection moulding companies.

2. Stadium Building Products

Overview

Of course, they don’t top our own list, but Stadium Building Products is a serious player in the UK building products sector. With a near 120-year history, Stadium has been supplying tradespeople and DIYers alike with products found in practically every builder’s merchant across the country. Recent brand refreshes and a new website have brought the business into the modern age while maintaining its strong reputation for reliability and quality.

Stadium is a brand Flambeau Europe is proud to have under its wing, as they are one of the best UK injection moulding companies when it comes to ventilation, plumbing and drainage, and so much more.

Capabilities

- Injection Moulding & Manufacturing: Durable, high-volume production for building, DIY, and industrial applications.

- Product Range: Buckets, bins, ventilation components, and other household and construction products.

- Black Hole Ventilator Technology: Innovative design delivers quieter, more discreet, and higher-performing ventilation solutions than competitors.

- Customer Reach: Extensive national distribution, supporting retailers, trade outlets, and direct-to-consumer channels.

Strengths

- Exceptional versatility across product lines and applications.

- Ability to scale production for seasonal demand and large projects.

- Trusted, well-established brand with decades of expertise.

- Ongoing innovation in product design and functionality.

Visit the Stadium Building Products website here.

3. Rhino Flexi Tubs, Buckets & Bins

Overview

Rhino Brand (a brand of Flambeau Europe) is the go-to solution for homeowners, gardeners, and DIY enthusiasts looking for durable and practical plastic products. You’ll find their products in practically every builders’ merchant, and even in retail chains such as Wickes. Recently, Rhino underwent a complete rebrand and modern makeover, elevating the brand while keeping its focus on practicality and performance.

Capabilities

- Injection Moulding & Product Variety: Produces tubs, buckets, bins, and storage solutions in a huge range of colours, sizes, and product types, covering nearly every market segment.

- Consumer-Focused Design: Ergonomically designed and highly durable products suitable for household, gardening, and general utility applications.

- Flexible Manufacturing & Supply: Capable of meeting seasonal demand spikes and large-volume orders for both trade and retail channels.

Strengths

- Wide-ranging product line meeting diverse consumer needs.

- High brand visibility and presence in both trade and retail markets.

- Strong design and usability focus, making everyday tasks easier.

- Recent brand and visual refresh ensure modern appeal while maintaining functionality.

You can learn more about what Rhino has to offer here.

4. Rutland Plastics

Overview

Rutland Plastics specialises in precision plastic components for industrial and commercial applications. They are known for high-quality manufacturing and tailored solutions for B2B clients.

Capabilities

- Injection moulding of complex parts.

- Design for manufacture and part optimisation.

- High-volume production for industrial sectors.

Strengths

- Strong engineering and technical expertise.

- Reliable supply for UK and European clients.

- Focus on consistency, quality, and regulatory compliance.

5. Goodfish Group

Overview

Goodfish Group delivers plastic injection moulding solutions across multiple industries, with a focus on flexible, client-driven services.

Capabilities

- Custom injection moulding for small to medium production runs.

- Engineering support for new product development.

- Variety of thermoplastic materials and finishes.

Strengths

- Highly adaptable to client requirements.

- Strong reputation for problem-solving and innovation.

- Dedicated customer support and project management.

6. Nordell

Overview

Nordell is a UK injection moulder providing precision components for industrial, automotive, and consumer sectors.

Capabilities

- Injection moulding for mid-to-large production volumes.

- Expertise in engineering plastics and high-precision parts.

- Focus on prototyping and repeatable production runs.

Strengths

- Established track record in precision engineering.

- Strong material knowledge and process control.

- ISO-certified processes ensuring quality and compliance.

7. Pentagon Plastics

Overview

Pentagon Plastics focuses on smaller-scale production of consumer and industrial plastic products.

Capabilities

- Injection and blow moulding for consumer goods.

- Production of custom containers, housings, and parts.

Strengths

- Flexible manufacturing for lower-volume orders.

- Quick turnaround times and tailored solutions.

8. Fisher Plastics

Overview

Fisher Plastics offers injection moulding services for industrial and commercial applications, specialising in robust and durable components.

Capabilities

- Custom injection moulded components.

- Engineering and design support for clients.

Strengths

- High-quality standards and repeatable manufacturing.

- Experienced technical team to support bespoke projects.

9. Biplas

Overview

Biplas produces custom plastic products for industrial, medical, and consumer sectors.

Capabilities

- Injection and compression moulding.

- Small-to-medium volume production.

Strengths

- Expertise in material selection and part design.

- Flexible approach to client requirements.

10. Amtek Plastics

Overview

Amtek Plastics provides injection moulding and assembly solutions for industrial and consumer applications.

Capabilities

- Custom thermoplastic component production.

- High-quality prototyping and production runs.

Strengths

- Responsive customer service and technical support.

- Focus on consistent, reliable quality for a wide range of products.

Bringing It All Together: The Best UK-Based Injection Moulding Companies

While we cheekily put ourselves at number one, it’s clear that the UK is home to a diverse and highly capable injection moulding sector. Every company on this list—from Flambeau Europe, Stadium Building Products, and Rhino, through to Rutland Plastics, Goodfish Group, Nordell, Pentagon Plastics, Fisher Plastics, Biplas, and Amtek Plastics—plays a vital role in supporting British manufacturing.

These businesses contribute to innovation, quality, and sustainability, and collectively help bring production closer to home, strengthening local supply chains, boosting the economy, and reducing reliance on overseas manufacturing. Whether it’s for DIY enthusiasts, homeowners, industrial clients, or global brands, each organisation provides valuable expertise and solutions tailored to a wide range of applications.

Conclusion: Find Your Injection Moulding Partner

Choosing the right injection moulding partner is key to turning ideas into reality efficiently, reliably, and cost-effectively. Whether you’re developing a single prototype, a large production run, or a fully integrated turnkey solution, the companies on this list can help you achieve your goals.

At Flambeau Europe, we combine decades of experience, a versatile fleet of 16 injection moulding machines (60–1700 tons), full turnkey capabilities, and a commitment to quality and innovation. Get in touch today to discuss how we can support your next project and help you benefit from bespoke plastic manufacturing solutions tailored to your needs.