How Robotics is Shaping Modern Injection Moulding

Robotics in manufacturing is transforming the way factories operate, and at Flambeau Europe, we’re at the forefront of this change. From injection moulding to post-production processes, automation is helping us deliver higher-quality components faster, safer, and more efficiently.

This shift isn’t just about speed; it’s about precision and consistency. With robotics integrated across our production line, we can match parts to the optimal process and machine, ensuring every component meets exacting standards.

For those curious about careers in manufacturing, this evolution highlights why manufacturing is still one of the most exciting industries to work in.

(Image Courtesy: Wevolver)

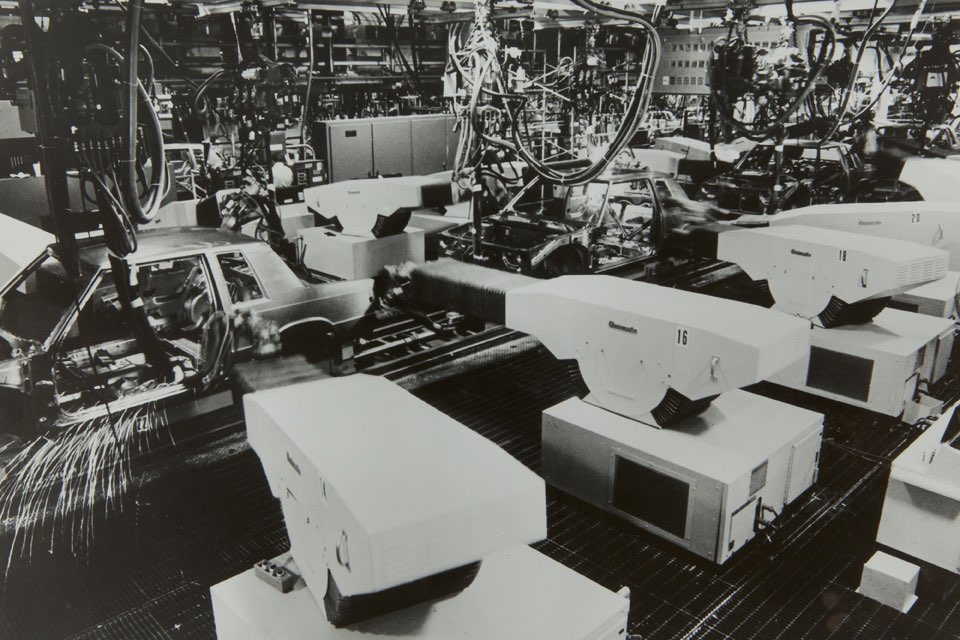

From Assembly Lines to Smart Injection Moulding

Robots have been part of manufacturing for decades, starting in the 1960s with simple industrial arms performing repetitive tasks. Over the years, robotics has evolved from basic automation to sophisticated systems capable of handling complex processes, including high-precision injection moulding and post-moulding operations.

Milestones in robotics have enabled factories to handle larger volumes, reduce errors, and allow human operators to focus on high-value tasks, rather than repetitive, time-consuming jobs. Today’s smart factories combine robotics, automation, and data analytics to optimise every step of production.

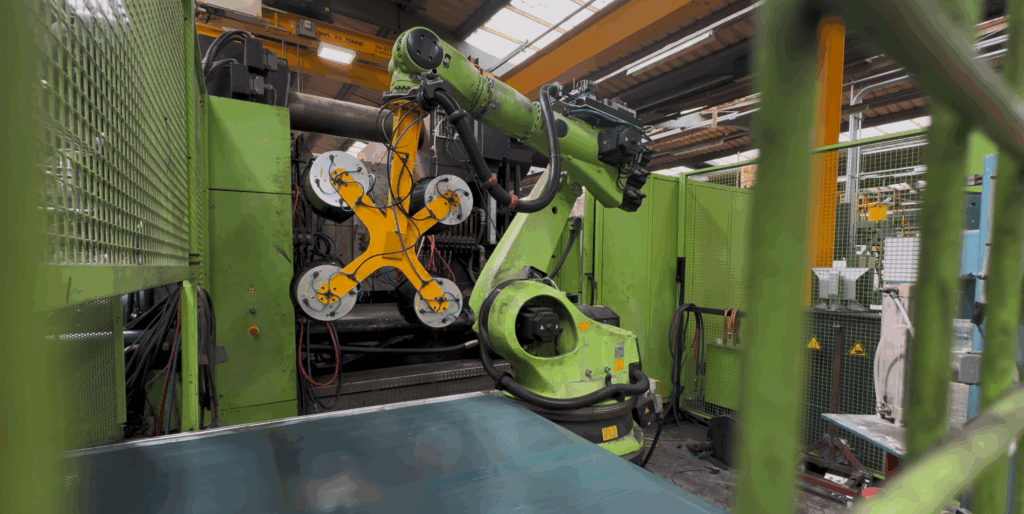

Robotics in Manufacturing Applications for Injection Moulding

Modern factories use robotics across nearly every stage of production. At Flambeau Europe, robotics plays a key role in:

- Material Handling: Automated systems transport raw plastics to injection moulding machines, reducing manual labour and improving safety.

- High-Precision Injection Moulding: Robots assist in setting up, monitoring, and adjusting moulds, ensuring complex, high-performance components are manufactured to exact specifications. Learn more about optimizing high-precision injection moulding.

- Post-Moulding Operations: Trimming, inspection, and assembly are enhanced by robotic systems, ensuring faster throughput and consistent quality.

These applications are not just about speed; they provide accuracy, repeatability, and scalability, allowing us to meet the evolving needs of our customers. Robotics in manufacturing is a key factor in driving innovation across the factory. See how automation in injection moulding is driving innovation at Flambeau Europe.

Why Robotics is Essential in Modern Factories

The benefits of robotics in manufacturing are clear:

- Efficiency and Productivity: Automated systems keep production moving consistently, reducing downtime and increasing output.

- Precision and Quality: Robotics ensure every component meets tight tolerances, reducing waste and rework.

- Worker Safety: Robots take over repetitive, hazardous tasks, allowing operators to focus on higher-value activities.

- Flexibility and Scalability: Modern systems can adapt to new products, different sizes, and changing production requirements.

By integrating robotics across injection moulding and downstream processes, Flambeau Europe can deliver faster, more reliable services without compromising on quality.

(Image Courtesy: SP Automation & Robotics)

Recent Developments in Robotics for Injection Moulding

The last decade has seen major advancements in robotics, especially for injection moulding and post-production:

- Collaborative Robots (Cobots): Work safely alongside humans on injection moulding lines, increasing flexibility. Learn about collaborative robots.

- AI-Driven Optimisation: Intelligent systems adjust moulding parameters in real-time, ensuring consistent quality and efficiency.

- Advanced Vision Systems: High-speed cameras and sensors detect defects immediately, improving quality control.

- Smart Factory Integration: Robotics now communicate with other systems to track production data, predict maintenance, and optimise workflow. See how smart factories are changing manufacturing.

These developments mean robotics no longer simply automates tasks, they enhance decision-making, efficiency, and quality across the production line.

(Image Courtesy: The Silicon Review)

The Future of Robotics in Manufacturing

The future of robotics in manufacturing is exciting. Emerging trends include:

- Fully Autonomous Production Lines: From raw material to finished component, every step could be automated.

- Predictive Maintenance: AI predicts equipment issues before they occur, reducing downtime.

- Advanced AI Integration: Machines can adapt dynamically to new product designs and changing specifications.

- Continued Growth in the UK Plastics Industry: Robotics will help UK manufacturers remain competitive and efficient.

These innovations will make factories more responsive, efficient, and capable of producing higher-quality components faster. Read more about the future of plastic manufacturing in the UK.

Embracing Robotics for Smarter Manufacturing

Robotics in manufacturing is no longer a futuristic concept — it’s a vital part of modern injection moulding and factory operations. At Flambeau Europe, we’re embracing automation to improve efficiency, precision, and quality across every stage of production.

If you’d like to learn how our production systems and advanced injection moulding capabilities can support your next project, get in touch via our contact page.