Flambeau Europe is a UK-based Injection Moulder that delivers complete and integrated solutions for businesses seeking reliable, scalable, and expert-led services. With decades of experience and a UK-based production facility equipped with advanced technology, we serve a diverse range of industries, from power tools and industrial electronics to ventilation and climate control.

What makes us different is our ability to manage projects from start to finish, all under one roof. At every stage, we focus on delivering value, quality, and efficiency.

End-to-End Injection Moulding UK Services

At Flambeau, we don’t just make parts — we engineer smart, practical solutions.. Our injection moulding capabilities cover every phase of production:

- Collaborative design and product development

- Tailored tooling supply, validation, and modification

- Advanced software analysis to improve material use and product strength

- Robotic finishing, assembly, and packaging for scalable production

Our engineers use data to guide material selection and structure, helping clients reduce weight, increase durability, and cut costs.

This full-service approach is trusted by major UK brands in the power tool, industrial electronics, and ventilation sectors.

Delivering Consistency at Scale

Precision and control are key in high-volume manufacturing — and that’s where Flambeau excels. For brands needing consistent output, we combine automation, human quality checks, and advanced technology.

We use robotics and in-line inspection systems to monitor parts as they exit the mould. This ensures tight tolerances and visual accuracy on every component.

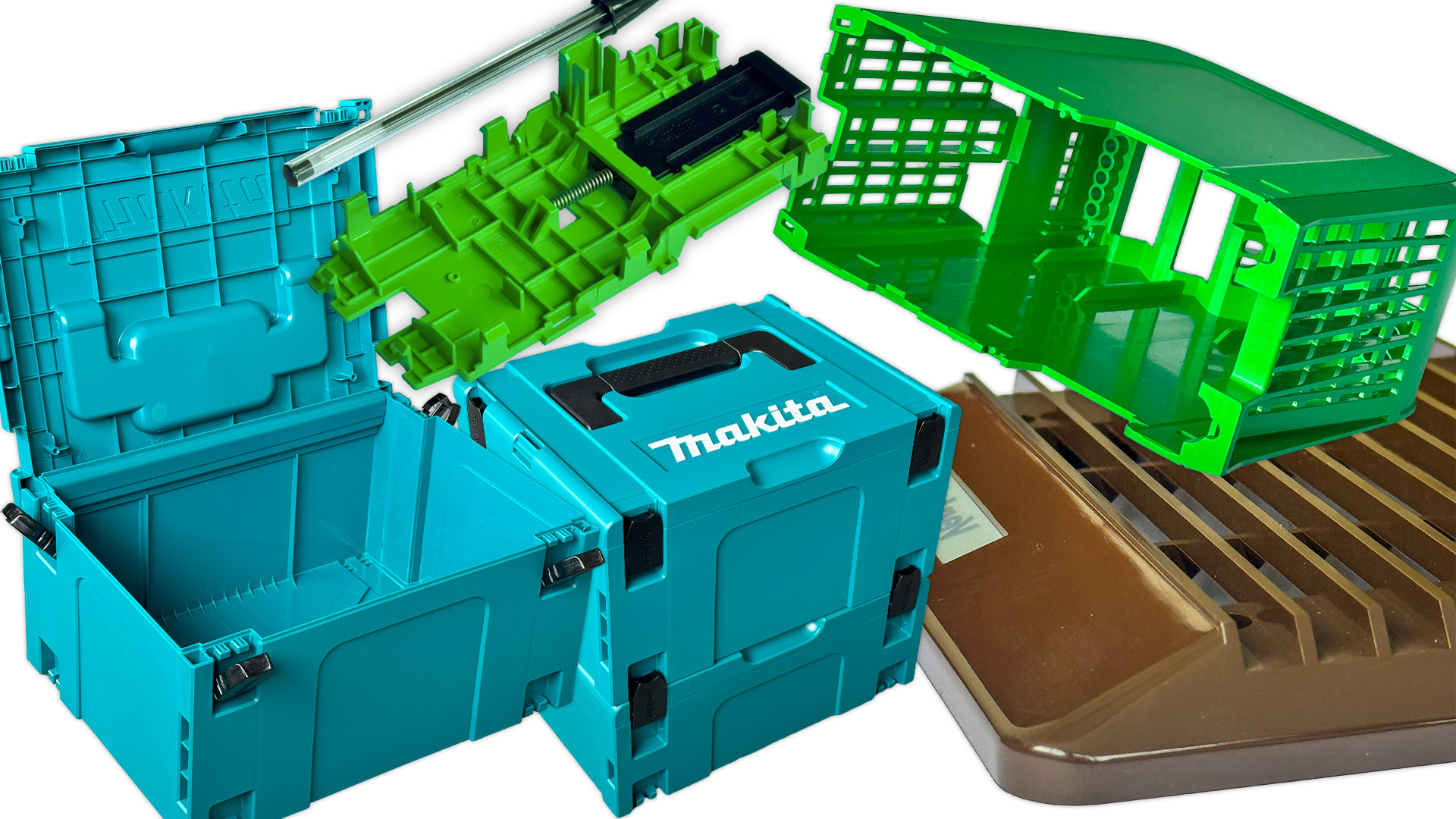

Our partnership with Makita is a prime example. We manufacture their distinctive blue tool cases, ensuring each one matches strict brand guidelines. To meet their high standards, we created a dedicated manufacturing cell where components are moulded, tightly packed, and inspected regularly. Using colour-matching scanners, our operators periodically check parts to confirm they meet global consistency targets.

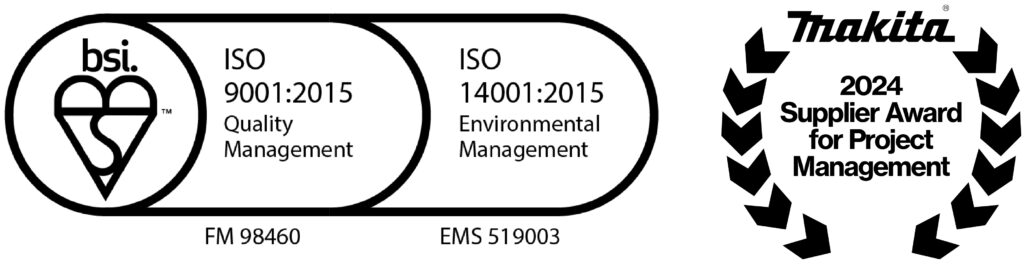

Our commitment to quality and collaboration earned us Makita’s Project Management Supplier of the Year award in 2024.

Read more about this award win in our blog post →

This combination of automation and human oversight shows how we scale up without sacrificing quality.

Tooling Expertise That Powers Product Performance

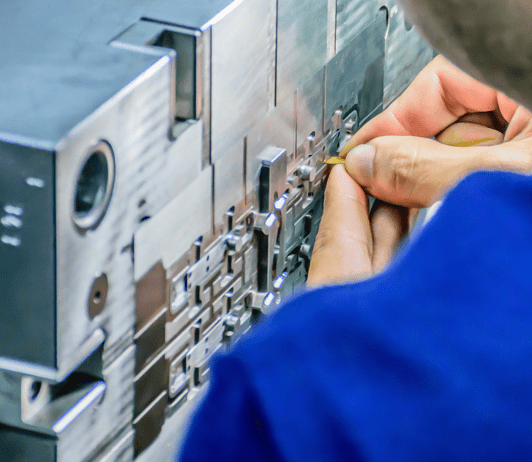

Tooling is the heart of any injection moulding project. Our in-house experts work directly with customers and toolmakers to create tools designed for precision, strength, and efficient production cycles processing that are capable of processing recycled polymers wherever agreed.

We use advanced CAD software to predict how tools will perform in real-world use. This lets us identify and resolve issues like weld lines or air traps early, which saves time and reduces risk.

Our tooling support includes:

- Gate and runner optimisation

- Structural analysis for stress points

- Tool modifications and lifecycle management

- Integration with post-moulding processes

Fewer tool iterations mean faster launches and more consistent quality.

Solving Complexity Through Engineering

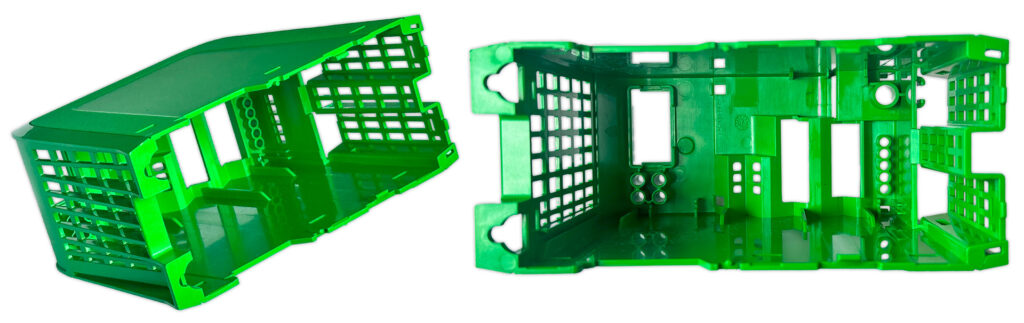

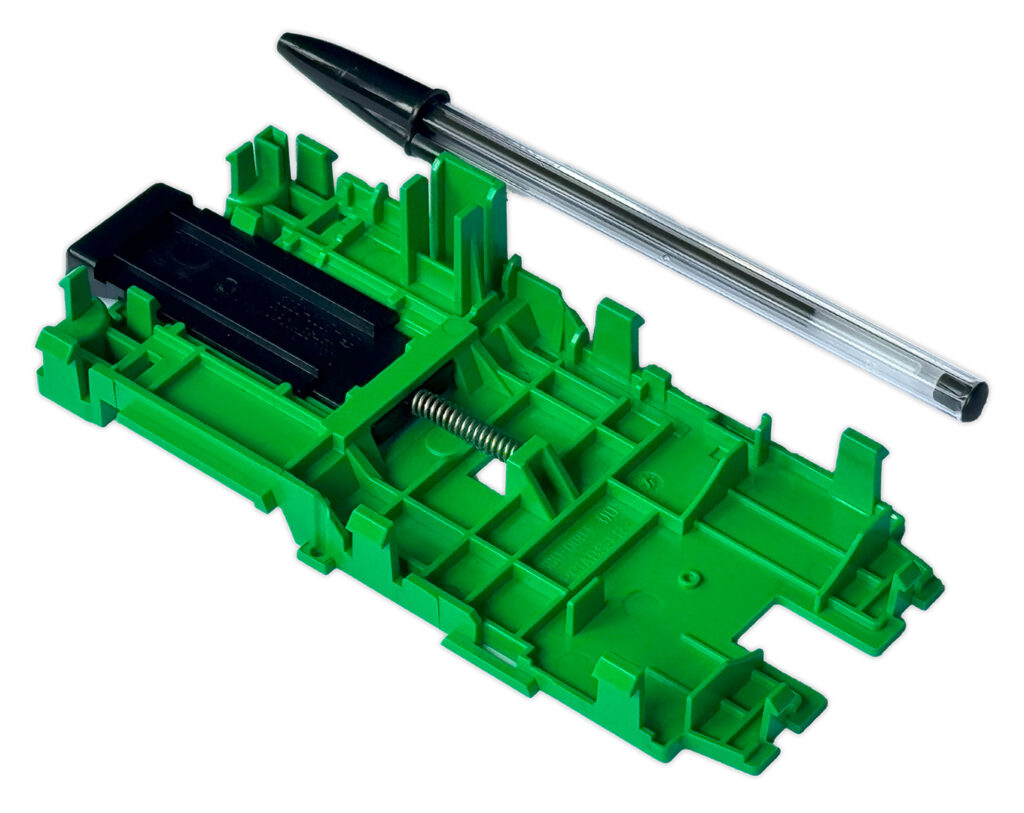

Our work with Nidec highlights how we solve complex injection moulding challenges in the UK. We produce detailed plastic casings for elevator electronics, where durability and dimensional precision are critical.

The casing design includes thin ventilation mesh and small mounting features, which pose risks for warping or weak points during production. We worked closely with our engineers, toolmakers, and Nidec’s team to design a mould that balanced part strength with cost efficiency.

Using software, we simulated fill patterns and made adjustments to gate placement and wall thickness.

These refinements help maintain structural integrity and ensure a smooth, repeatable process to ensure consistent quality over time.

Supporting Ventilation and Climate Control Brands

Flambeau’s injection moulding capabilities also extend to the ventilation sector, where we support multiple brands within the Volution Group that dates back over 38 years. Our solutions are tailored to accommodate both complex geometries and variable production volumes, offering flexibility for R&D teams and reliability for supply chains.

We regularly provide:

- High-precision moulded housings

- Modular components for airflow systems

- End-to-end assembly and packaging

- Scalability for fluctuating demand

Our systems are built for responsiveness, allowing us to ramp up quickly while maintaining high standards.

Built for Industrial Injection Moulding UK Demands

Across every project, Flambeau brings together consistency, innovation, and adaptability. Whether it’s strengthening a part design, managing high-output production, or supporting sustainability goals, we’re more than a supplier — we’re a strategic partner.

With a UK-based site and global support network, we offer fast, effective solutions tailored to each customer’s needs.

Your Trusted Partner for Injection Moulding UK services

Flambeau Europe is built to deliver. From design and tooling to automation and assembly, our injection moulding UK capabilities are trusted by industry leaders for good reason.

Looking for a partner who understands your requirements and can deliver high-quality parts at scale?

Contact our team today to discuss how we can support your next injection moulded product from concept through to completion.