Finding the right injection moulding partner can make or break your production schedule, quality standards, and overall project success. If you’re trying to find an injection moulding partner who is reliable, capable, and aligned with your business needs, it’s essential to know what factors to consider. Partnering with the wrong supplier can lead to delays, increased costs, and subpar products—but with the right approach, you can secure a partner who drives growth and efficiency.

This guide explores the key considerations, common red flags, and how Flambeau Europe supports businesses seeking a trusted injection moulding partner.

Why It’s Crucial to Find an Injection Moulding Partner You Can Trust

Your injection moulding partner isn’t just a supplier—they are a critical part of your production chain. Choosing wisely affects:

- Timelines: Can your partner meet deadlines without compromising quality?

- Consistency: Will your products maintain high standards across every batch?

- Scalability: Can they support growth or handle sudden increases in volume?

Have you considered how a partner could impact your bottom line? At Flambeau Europe, we work closely with clients to ensure each project runs smoothly. Learn more about our Complete Bespoke Solutions and how we tailor services to every client.

Key Factors to Consider When Selecting a Partner

Find an Injection Moulding Partner With Proven Experience and Industry Knowledge

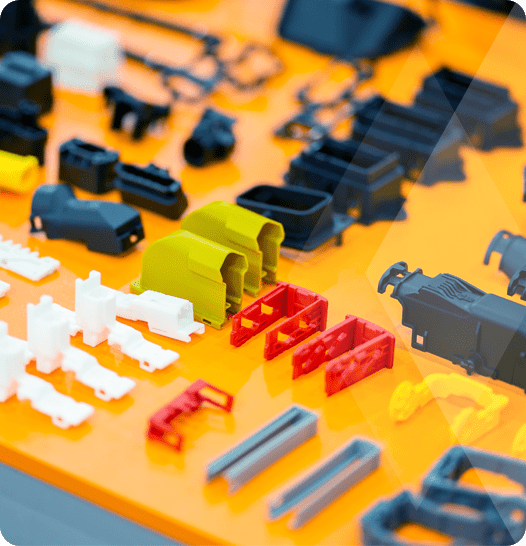

A partner with industry expertise can guide your project from concept to completion. Whether you operate in automotive, medical, consumer, or industrial sectors, experience ensures that your designs are manufacturable and meet regulatory requirements.

Quality Assurance and Certifications

Reliable partners uphold rigorous quality standards. Certifications like ISO 9001, ISO 14001, and ISO 45001 signal a commitment to quality, safety, and sustainability. For more information on why certifications matter, you can check out this article on ISO-certified injection moulders, awarded to Flambeau Europe by BSI.

To learn more about the standards behind these certifications, you can visit the British Standards Institution (BSI) website. BSI sets internationally recognised benchmarks for quality, environmental management, and safety, helping businesses identify trustworthy and compliant injection moulding partners.

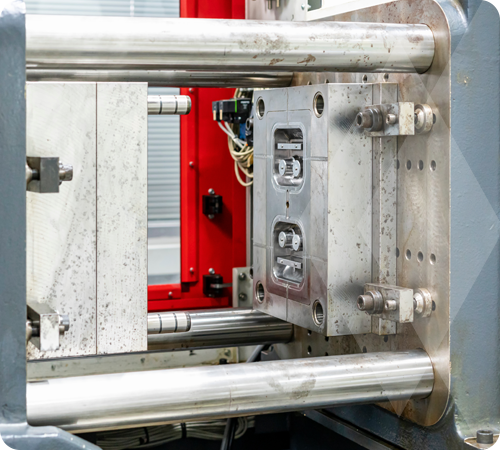

Find an Injection Moulding Partner With Modern Capabilities and Technology

Different projects require different production capabilities. Check that your partner has the right machinery, including varying tonnage, multi-shot capabilities, and automation options. Ensure they can support both prototyping and high-volume production.

Communication and Customer Support

Transparent communication keeps projects on track. Look for a partner who provides clear updates, offers proactive solutions, and assigns dedicated project managers. Ask yourself: Do you feel confident your supplier will keep you informed every step of the way?

Sustainability and Environmental Responsibility

Eco-conscious processes are increasingly important. A partner who invests in recycling, waste reduction, and eco-friendly materials demonstrates responsibility for both the environment and your brand. Learn more about sustainable practices in injection moulding in Flambeau’s eco-friendly injection moulding trends.

Common Red Flags When Searching for an Injection Moulding Partner

Even experienced businesses can be caught off guard by hidden issues. Watch out for suppliers who:

- Offer vague pricing or unexpected fees

- Unreliable machine capacity planning

- Lack of traceable references or case studies

- Cannot provide certifications or evidence of compliance

- Struggle with communication or project management

Avoiding these pitfalls ensures smoother production and protects your bottom line. You can read more about our top 5 red flags to watch out for when choosing an injection moulding partner in our article here.

How Flambeau Europe Supports Your Injection Moulding Needs

At Flambeau Europe, we prioritise partnership. Our clients benefit from:

- Dedicated account management with open communication

- In-depth understanding of existing capabilities with a willingness to invest

- Extensive experience across multiple sectors

- Full ISO certification for quality, safety, and sustainability

- Modern automated machinery fleet capable of handling prototyping up to high-volume runs

If you’re looking for a reliable injection moulding partner, you’re in the right place.

Conclusion: Find and Injection Moulding Partner with Confidence

Selecting the right injection moulding partner requires careful consideration, attention to quality, and a trusted relationship. By evaluating experience, capabilities, certifications, communication, and sustainability, you can minimise risks and maximise efficiency. If you’re looking for a partner who meets all these criteria, you’ve already found them. Flambeau Europe is ready to help bring your next project to life.

Ready to take the next step? Reach out to Flambeau Europe today via our Contact page or explore our injection moulding capabilities page to see how we can support your next project.