Introduction

Choosing an injection moulding partner is a critical decision that can have lasting effects on your product quality, lead times, and bottom line. With numerous providers available, it can be tempting to rush into a partnership based solely on price or lead time. But failing to do your due diligence could lead to costly errors, delays, or even complete project failure. In this post, we’ll explore five major red flags to watch out for when selecting an injection moulding company — and offer tips on how to find a reliable, transparent partner that aligns with your business goals.

Why Due Diligence Matters When Choosing an Injection Moulding Partner

Injection moulders vary greatly in quality, capability, and reliability. Some may lack the technical expertise or facilities to deliver consistent quality. Some injection moulders lack the infrastructure or flexibility to manage complex or time-sensitive projects. Asking the right questions and spotting early warning signs can help you avoid costly mistakes. So how can you separate a reliable supplier from one that might let you down?

Red Flag 1: Lack of Certifications or Compliance

When choosing an injection moulding partner, industry certifications like ISO 9001 and ISO 14001 aren’t just optional extras; they’re proof of commitment to quality and environmental standards. If a manufacturer can’t produce documentation or doesn’t mention these standards at all, it’s time to ask: What corners might they be cutting?

At Flambeau Europe, our ISO 9001 accreditation ensures consistent quality across all our products and processes, while our ISO 14001 certification demonstrates our active efforts to reduce our environmental impact. These accreditations aren’t just checkboxes — they reflect the high standards we hold ourselves to and offer reassurance to partners that we operate with precision, responsibility, and trustworthiness. You can learn more about the ISO 9001 and ISO 14001 standards on the official BSI website.

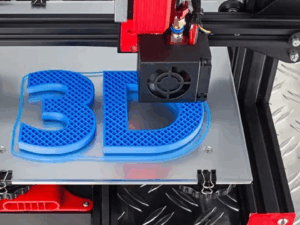

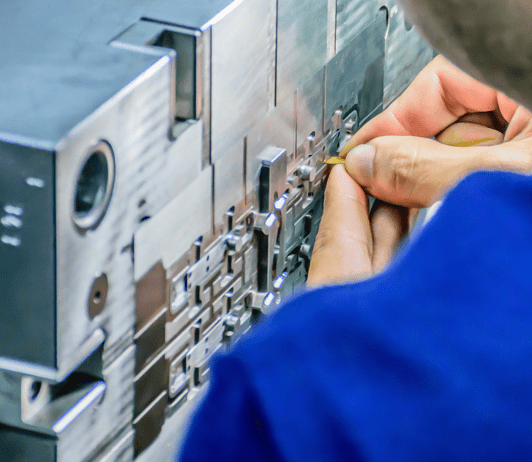

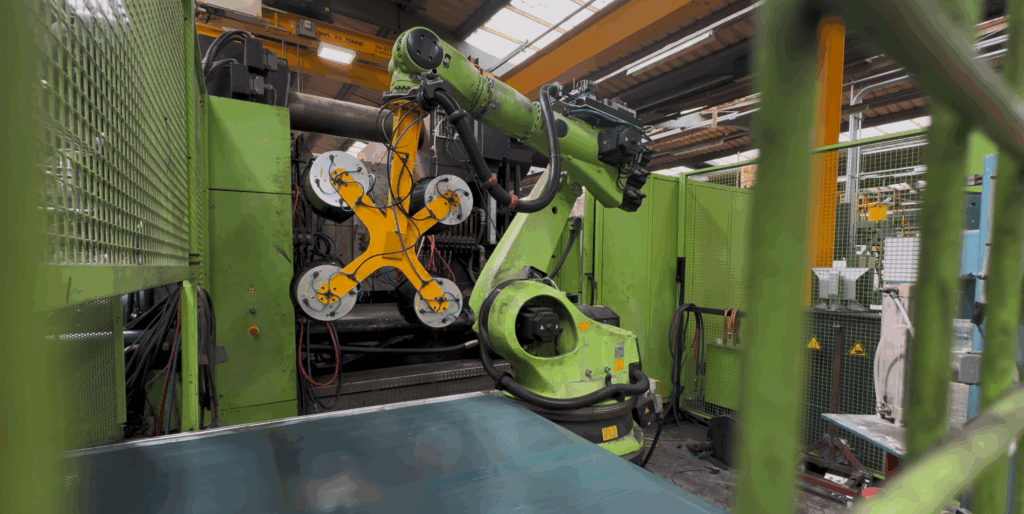

Red Flag 2: Limited Capabilities or Technology

Does the partner have a wide range of modern injection moulding machines? Do they have capacity or space to expand to meet your needs? Are they equipped for both high- and low-volume production? If a supplier lacks in-house tooling capabilities or is outsourcing large parts of the process, you risk delays and inconsistent quality.

Flambeau Europe offers complete bespoke solutions in-house, from initial design and tooling development to injection moulding, testing, and final delivery. We invest in state-of-the-art machinery and continuously evolve our capabilities to meet changing market needs. Whether you need technical components, multi-shot moulding, decoration options, or value-added assembly, we’re fully equipped to deliver efficiently and at scale.

💡 Have you considered what delays or costs might occur if your moulding partner lacks end-to-end capability?

Red Flag 3: Experience Matters When Choosing an Injection Moulding Partner

Trust is earned through experience. If a manufacturer can’t show relevant case studies or a proven track record in your industry, proceed with caution. Working with an established injection moulding company means you’ll benefit from their expertise, industry-specific insight, and problem-solving capabilities.

At Flambeau Europe, our work spans key industries including automotive, hygiene, packaging, and defence. Our deep experience means we can anticipate challenges, tailor solutions, and meet stringent industry standards. Clients trust us to deliver on complex requirements because we’ve done it time and again. We don’t just make products… We solve problems and build long-term partnerships, and have won customer rewards as a result.

🔍 Do you want to be someone’s “trial run”?

Red Flag 4: Poor Communication and Project Management

Your injection moulding partner should be just that — a partner. If you’re dealing with unclear timelines, unreturned calls, or siloed communication, that’s a big red flag. Transparency and responsiveness are essential for successful product development and scale-up.

Flambeau stands out with our clear and collaborative communication approach, supported by expert project managers and technical leads. We guide clients through each phase of the complete bespoke solution journey, ensuring expectations are aligned from concept to completion. Our team becomes an extension of yours, with a shared focus on quality, timelines, and transparency.

💬 Wouldn’t it be easier to work with a team that feels like an extension of your own?

Red Flag 5: Sustainability Oversight When Choosing an Injection Moulding Partner

Today, more businesses are looking to reduce their environmental impact, and your injection moulding supplier should reflect those values. A partner with no visible sustainability practices or material recycling capabilities may not be future-ready.

We’re proud to champion eco-friendly injection moulding practices at Flambeau Europe. Our sustainable processes include recycled material usage, energy-efficient moulding technologies, and waste reduction practices. Additionally, our proactive outreach, such as inspiring the next generation through STEM and engineering initiatives, demonstrates our long-term commitment to a more responsible future in manufacturing.

🌱 How will your brand’s values align with theirs when it comes to sustainability?

What Can Go Wrong If You Ignore the Red Flags?

Choosing the wrong injection moulding partner can result in:

- Costly tooling mistakes

- Delayed product launches

- Supply chain disruption

- Quality defects that damage your reputation

- Non-compliance with regulations

Choose a partner who brings experience, ethics, and technical expertise to the table — not one who leaves you in the lurch.

Conclusion: Make an Informed Decision

Choosing an injection moulding partner is not just about price — it’s about trust, transparency, and long-term performance. By staying alert to these red flags and asking the right questions early, you can avoid wasted time, hidden costs, and product recalls. Work with a company that shares your values and can demonstrate results.

Take the Next Step with Flambeau Europe

Flambeau Europe offers more than just injection moulding; we deliver end-to-end support, technical expertise, and sustainable practices that help your products succeed.

📩 Explore our Complete Bespoke Solutions

🔍 Learn about Careers in Manufacturing

🌍 Read how we’re inspiring the next generation

📞 Contact our team to discuss your next project.