When selecting a manufacturing partner, it’s tempting to chase the lowest unit price. But for modern businesses, it’s the cost savings with UK injection moulders that deliver real value — not just cheaper mouldings, but lower total ownership costs across freight, rework, lead times, and stock holding.

This blog explores why UK injection moulding is more cost-efficient than ever and how Flambeau Europe helps customers save without compromising on quality.

Why Offshoring Isn’t What It Used to Be

Recent global events have dramatically reshaped global manufacturing and logistics, exposing the hidden costs and vulnerabilities of offshore production.

The COVID‑19 pandemic disrupted factory operations worldwide and caused severe supply chain breakdowns. Industrial production fell sharply, port congestion increased dramatically, and over 90% of large companies experienced significant delays or shortages (E-BI).

In the UK, Brexit introduced new customs procedures, tariffs, and compliance costs, making EU–UK trade slower and less predictable. These administrative burdens have increased both lead times and landed costs for offshore-sourced components and products.

The war in Ukraine has added further complexity by contributing to global fuel inflation and impacting supply routes across Europe and Asia. Meanwhile, the Red Sea crisis — triggered by Houthi attacks on commercial vessels — has forced container ships to reroute around Africa, adding 10–14 days of travel time and pushing up shipping costs by as much as 300% (Atlas Institute).

These events reveal that the “cheaper” option of offshore injection moulding often comes with unpredictable costs and delays. Choosing a reliable, UK-based partner offers a more stable, transparent, and resilient alternative, one that aligns with long-term operational goals rather than short-term unit price comparisons.

Cost Savings with UK Injection Moulders #1: Lower Logistics and Freight Costs

Freight costs from Asia and even Europe have soared in recent years. Ocean freight, insurance, import charges, and port handling fees can add up fast, especially for bulky or frequent shipments.

Working with a UK injection moulder cuts out these global logistics costs, leaving delivery costs within the UK only, while also reducing carbon emissions and risk exposure.

➡️ Navigating Supply Chain Disruptions: Why Choosing a Reliable Injection Moulding Partner Matters

Cost Savings with UK Injection Moulders #2: No Import Duties or Paperwork Hassles

Even imports from Europe can now face duty charges, delays, and customs declarations post-Brexit. These extra steps create unpredictable costs and planning issues.

Domestic sourcing simplifies everything… No surprise tariffs, no language barriers, no long-winded documentation processes.

Cost Saving #3: Faster Lead Times, Reduced Inventory Costs

Offshoring often necessitates over-ordering and stockpiling to compensate for long lead times. That ties up capital in warehouse space and purchased goods waiting to be assembled.

With Flambeau Europe, our clients enjoy faster production and delivery, meaning smaller batch sizes, leaner stockholding, and more agile operations.

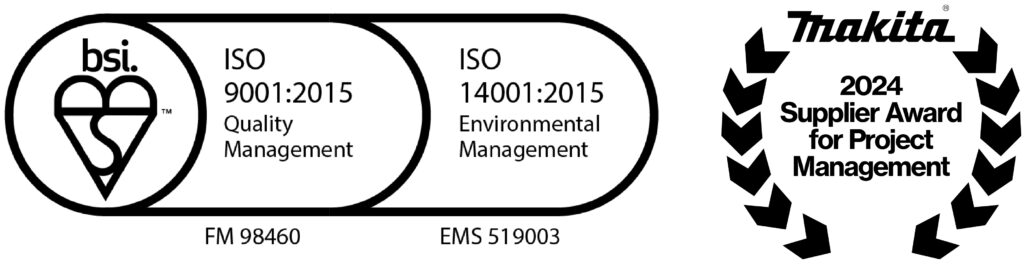

➡️ Award-Winning UK Injection Moulding: Flambeau Europe Recognised by Makita

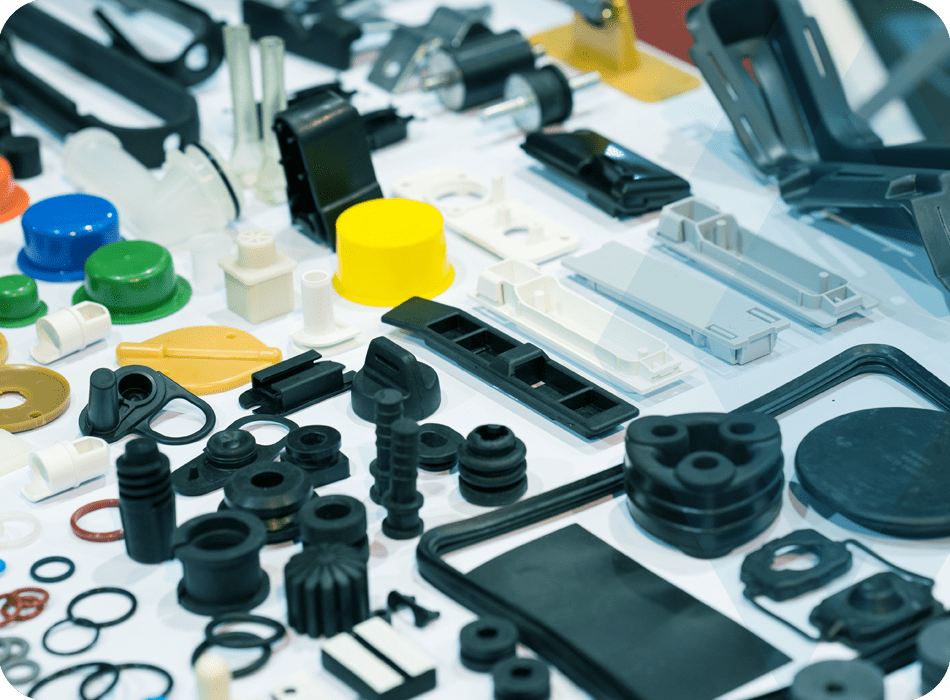

Cost Saving #4: Lower Rework and Returns Through Quality Assurance

Distance often makes quality control harder. If defects arise, getting replacements shipped can take weeks — sometimes months.

At Flambeau, our ISO-certified processes ensure consistently high-quality output. We collaborate closely with clients to deliver parts right the first time.

➡️ Why Choosing an ISO Certified Injection Moulder Matters

Cost Saving #5: Better Collaboration and Quicker Design Iteration

Innovation works best when teams are aligned in real-time. With local support, UK customers benefit from instant communication, face-to-face workshops, and on-site reviews.

The result? Better product development, smoother launches, and fewer costly delays.

➡️ UK-based Injection Moulder: How Flambeau Delivers Tailored Solutions for Every Industry

What These Cost Savings Mean for Your Business

By working with a UK injection moulder, you’re not just buying plastic parts, you’re investing in resilience, cost control, and agility.

The cost savings with UK injection moulders go far beyond the moulding machine — they touch every part of your supply chain and bottom line.

Why Flambeau Europe Is the Right UK-Based Injection Moulding Partner

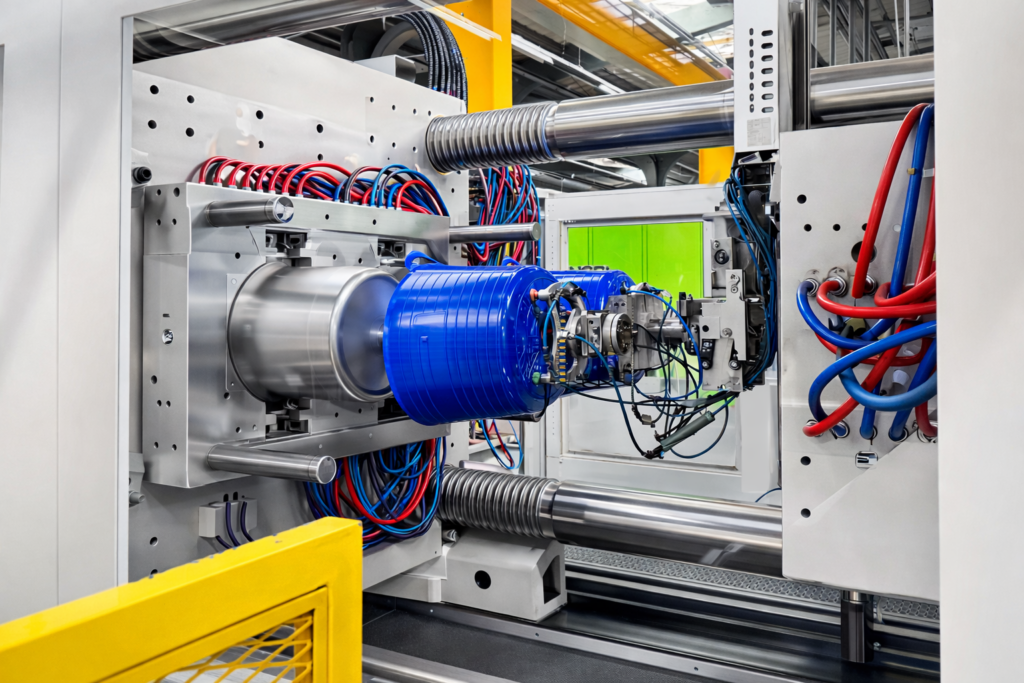

Flambeau Europe is part of a global manufacturing group, with the capabilities, people, and scale to serve complex, high-volume programmes, all from our Kent headquarters.

✅ In-house tool design & development

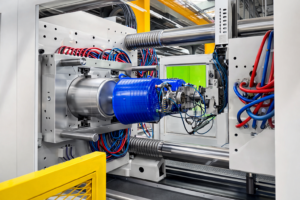

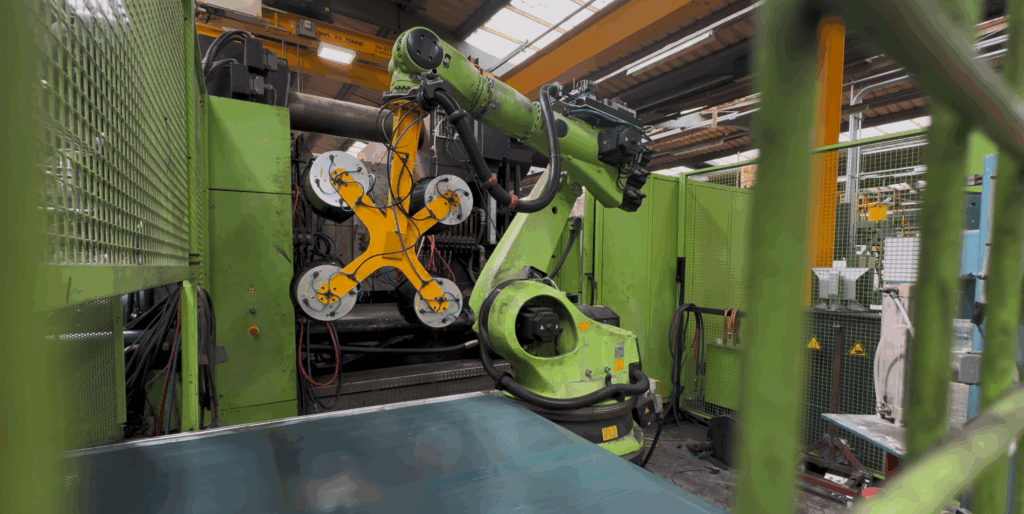

✅ Injection moulding from 60 to 1700 tons across 21 machines

✅ ISO 9001, 14001, and 45001 accredited

✅ Dedicated account management and engineering teams

✅ Over 70 years of experience in plastic manufacturing

Start Your Cost-Saving Journey Today

If you’re ready to reduce risk, improve margins, and take control of your supply chain, we’re ready to help.